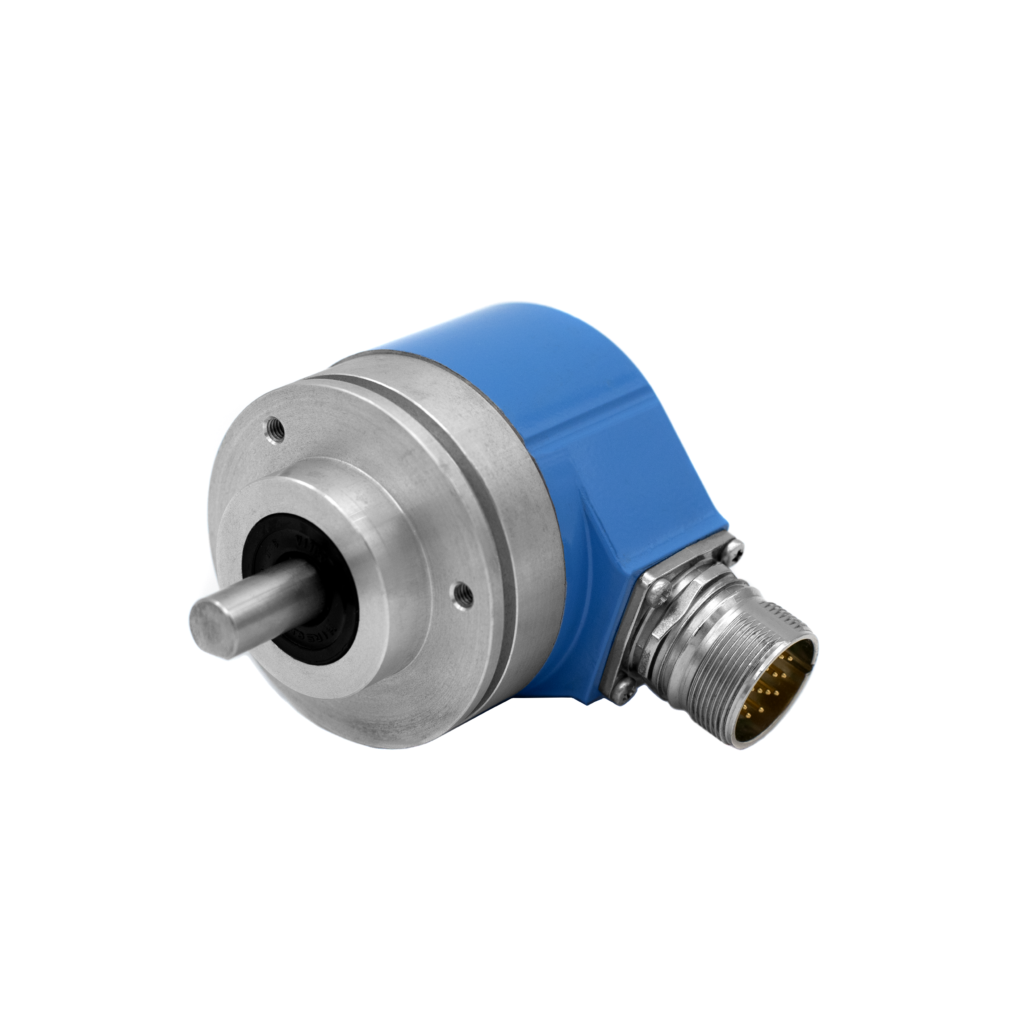

Rotary encoder – structure and function

- No Comments

The basic principle of the encoder is the conversion of mechanical movements into electrical signals. These pulses can be used to determine speed, position and length. For this reason, the rotary encoder is also often referred to as an encoder or angle encoder.

What types of encoders are there?

Generally, there are two categories, absolute encoders and incremental encoders.

Absolute encoders:

These are further divided into two different types of encoders. On the one hand the singleturn encoder, this detects movements with an angle of up to 360°. In comparison, multiturn encoders can detect positions over several revolutions.

Incremental encoders:

These provide a certain number of pulses per shaft revolution. The speed of a movement or a position is determined by measuring the period or counting the pulses per time unit.

Which measuring principles are there?

Magnetic measuring principle:

Magnetic encoders determine an angular position using magnetic field sensors based on the Hall effect. A permanent magnet attached to the shaft of the encoder generates a magnetic field that is measured by the sensor, which in turn generates a distinctive, absolute position value.

Optical measuring principle:

The most important component in an optical encoder is the code disk mounted on the encoder. Infrared light from an LED shines through the code disk onto an array of photoreceptors. When the rotating disk releases the light through the slits or transparent segments to the photocell, a signal pulse is generated. The generated signal is amplified and converted into a square wave. Thus, up to 32768 pulses can be achieved.

Where are rotary encoders used?

Rotary encoders are used in all areas of industry. For example, rotary encoders are frequently represented in medical technology, bearing and conveyor technology, and the automotive industry.