Lasercutting with laser cutting machines

- No Comments

Laser processing with Laserschneidemaschinen is a highly specialized technique based on the precise application of laser light for material manipulation. This innovative technology has made significant strides in recent years and plays a crucial role in various industries. By harnessing high-energy light, laser processing not only allows for extremely precise cuts but also opens up a world of versatility in working with metals, textiles, wood, and more. In this exploration, we will delve into the fundamental principles, applications, and promising future potential of laser processing.

Basics of Laser Processing

Laser processing with Laserschneidemaschinen is based on the principle of using laser light for precise material manipulation. It involves the use of a high-energy light beam directed through various materials. The basic elements of this process include:

-

Laser Light Source:

A laser generates a focused light beam directed towards the material to be processed. The choice of the laser source depends on the specific requirements of the processing. -

Material Preparation:

The material to be processed must be prepared accordingly to achieve optimal results. This may involve adjusting thickness, alignment, and surface characteristics. -

Focusing the Light Beam:

Lenses or mirrors focus the laser beam onto the material. Proper focusing is crucial for precise cuts and engravings. -

Control System:

A precise control system directs the laser beam over the area to be processed. Modern systems often use Computer Numeric Control (CNC) technology for accurate control. -

Power Control:

Adjusting the laser power influences cutting or engraving speed and the quality of the end product. Precise power control is crucial for adapting to different materials.

Applications of Laserschneidemaschinen

The versatility of Laserschneidemaschinen is reflected in a wide range of applications that have revolutionized various industries. Here are some significant application areas:

-

Metal Processing:

Laserschneidemaschinen are used in the metal industry to perform precise cuts in various metals, ranging from thin sheets to thicker metal plates. -

Textile Industry:

In the fashion and textile industry, laser processing enables the precise cutting of fabrics, preventing fraying and allowing for complex patterns and designs. -

Woodworking:

Laserschneidemaschinen find applications in woodworking by enabling precise cuts in different types of wood. This is particularly useful in furniture and decorative element manufacturing. -

Paper Industry:

In the paper industry, Laserschneidemaschinen provide the ability to cut complex shapes and designs in paper, often used in the production of packaging or creative paper products. -

Electronics Industry:

In the manufacturing of electronic components, laser processing enables precise cuts and engravings on circuit boards and other delicate materials. -

Automotive Industry:

In the production of automotive parts, Laserschneidemaschinen contribute to precise cuts in metal and plastic components, optimizing manufacturing processes. -

Construction:

In the construction industry, Laserschneidemaschinen are used for the precise processing of building materials such as steel beams and metal sheets.

Advantages of Laser Processing

Laser processing with Laserschneidemaschinen offers a variety of advantages, making it a preferred method in modern manufacturing. Here are some key factors:

-

Precision:

The precise cuts and engravings achievable with Laserschneidemaschinen allow for the production of products with extreme accuracy and detail. -

Efficiency:

The high speed and repeatability of laser processing significantly enhance the efficiency of manufacturing processes, leading to faster production. -

Versatility:

Laserschneidemaschinen can process a wide range of materials, including metals, plastics, textiles, wood, and more. This versatility makes them applicable to various industries. -

Low Material Waste:

The precise focus of the laser beam affects only the material intended for processing, reducing material waste compared to traditional processing methods. -

Flexibility in Shaping:

Laser processing enables the production of complex shapes and designs that may be challenging to achieve with other methods, opening up creative possibilities in product design. -

Contactless Processing:

As the laser beam processes the material without physical contact, there is no physical stress or wear on tools. This results in less wear and longer tool lifespans.

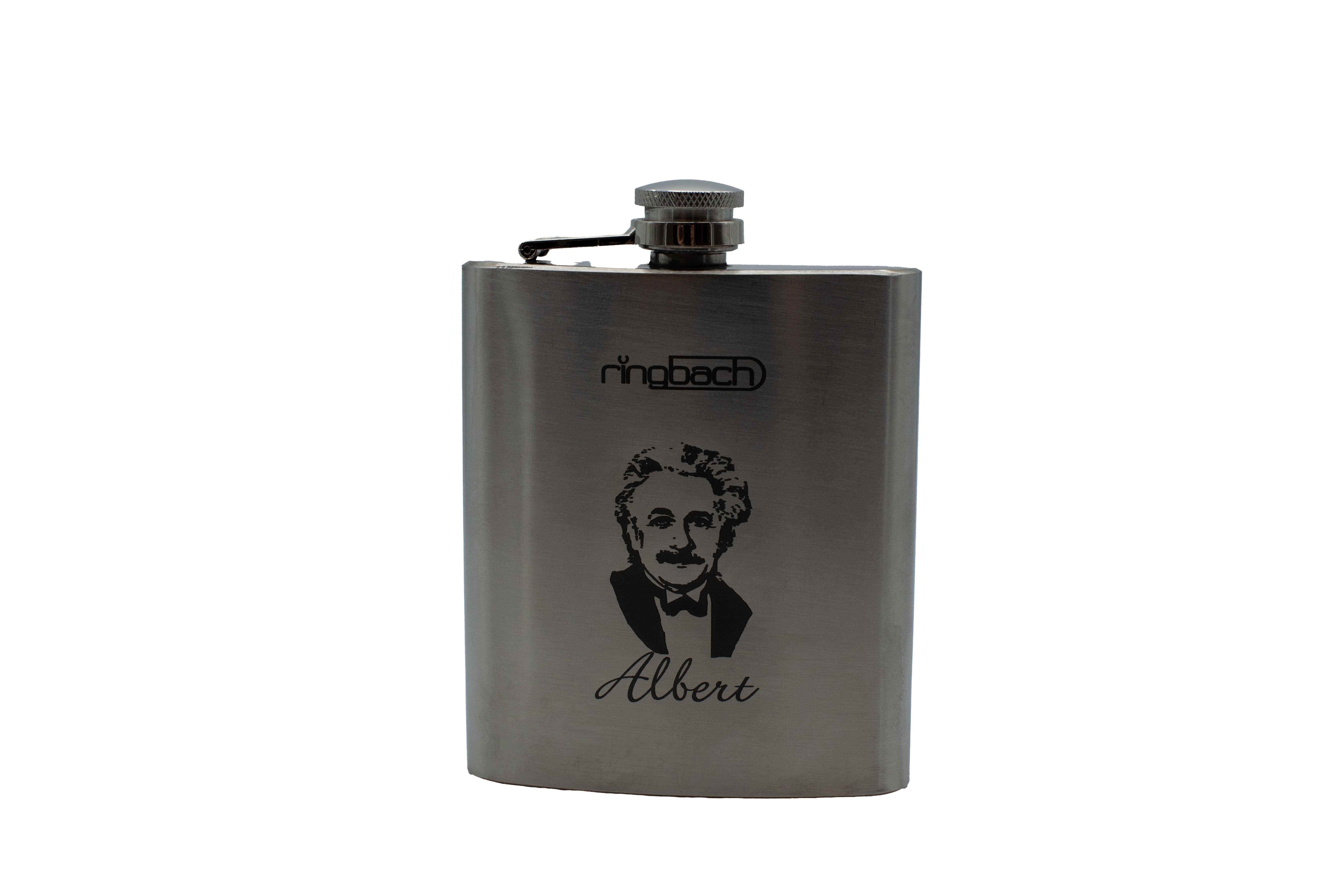

Laser cutting machines at ringbach

In our company, the integration of Laserschneidemaschinen has played a crucial role in our manufacturing strategy. The precise and efficient capabilities offered by laser processing have optimized our production processes and prototype construction, enhancing the quality of our end products.

By using Laserschneidemaschinen from Universal Laser Systems, we can precisely meet the individual requirements of our customers and provide customized solutions. Whether it’s fine cuts in metal components or detailed engraving on wood, laser processing allows us to work flexibly and with extreme precision.

The benefits of minimal material waste and contactless processing have not only contributed to a more sustainable production but also optimized our cost structure. This is reflected not only in the quality of our products but also contributes to a more competitive position in the market.

Looking to the future, we recognize the continuous advancements in laser processing technology. We are committed to investing in innovative solutions and ensuring that our production facilities are always up-to-date with these developments. Laser processing is not just a technology for us, it is a crucial part of our company strategy to meet the ever-growing demands of the market.

Laser services at ringbach

At ringbach, we offer laser services for the optimized production of your products or prototypes. With our VLS3.50 Laser from Universal Laser Systems, we can process, engrave, mark, cut, or label various materials. If you are interested, feel free to send us a non-binding inquiry.

For additional information, please feel free to read our >> Case Study <<.

Conclusion

Laser processing with Laserschneidemaschinen has established itself as a transformative force in the manufacturing industry, combining precision, efficiency, and versatility. From metal processing to the textile industry and woodworking, this innovative technology has revolutionized how we manipulate materials.

The precise cuts, efficiency, and diverse applications make laser processing an indispensable tool in various industries. However, the future promises even more exciting developments. Advances in laser processing technology, including improved efficiency, an expanded range of materials, and the integration of AI-driven systems, point to a promising evolution. These innovations will further expand the capabilities of laser processing and open new horizons for the manufacturing industry.

In a world where precision and speed are crucial, laser processing will continue to play a central role, paving the way for groundbreaking advances. The era of laser processing has just begun, and the coming years promise an exciting journey full of innovation and further breakthroughs.

Sources: