3D printing for rapid prototyping and product development

- No Comments

3D printing has revolutionized the prototyping and product design process. This technology allows for the transformation of digital designs into physical models, fundamentally changing the way companies develop products. In this article, we will explore the diverse applications of 3D printing in prototyping and product development, examining how it promotes innovation and efficiency.

Prototyping with 3D Printing

- Speed and Agility:

One of the major advantages of 3D printing in prototyping is its speed. Companies can easily implement design changes and create updated prototypes within a short period, significantly accelerating the development process. - Cost Savings:

Compared to traditional manufacturing methods, the costs associated with 3D printing prototypes are often lower. This allows companies to create more design iterations without exceeding their budget. - Complexity and Customization:

3D printing enables the production of prototypes with complex shapes and structures that would be challenging to achieve with conventional methods. This opens up entirely new design possibilities. - Error Detection and Optimization:

Prototypes can be used to identify and rectify potential design flaws early on, minimizing the risk of costly changes in later production phases.

Product Development with 3D Printing

3D printing extends beyond prototyping and has become an integral part of the entire product development cycle. Here are some examples of product development with 3D printing in businesses:

- Design Optimization:

Engineers and designers can swiftly bring their creative ideas to life by creating prototypes and models quickly and precisely. This facilitates design optimization and adaptation to specific requirements. - Rapid Tooling:

Companies use 3D printing to manufacture tools and molds for mass production, significantly speeding up the transition from product development to manufacturing. - Customization:

3D printing allows for the production of customized products tailored to the specific needs and desires of customers, especially in industries like medicine or consumer goods. - Cost Reduction:

The ability to produce complex components in a single printing process significantly reduces assembly and material costs, contributing to cost savings in product development. - Prototyping and Market Launch:

Fast prototyping enables companies to bring their products to market more quickly, gaining a competitive edge.

3D Printing and Design Innovation

3D printing has not only changed how products are developed but has also expanded the possibilities for creative design innovation. Designers and engineers now have tools that enable them to realize unique and complex designs that were previously challenging to implement. Here are some aspects of design innovation related to 3D printing:

- Complex Geometries:

3D printing allows for the creation of parts with intricate and organic geometries, enabling designers to craft shapes and structures that were not feasible with traditional manufacturing methods. - Lightweight Construction:

The ability to create internally hollow structures makes 3D-printed products lighter yet strong and stable, particularly important in aerospace and automotive industries. - Adaptation and Personalization:

3D printing enables companies to tailor products to the specific needs and desires of their customers, ranging from personalized smartphone cases to custom-made medical implants. - Prototypes for Market Research:

Designers can quickly create prototypes and present them to potential customers for feedback. This accelerates the innovation process and contributes to the development of market-ready products. - Rapid Design Iteration:

With 3D printing, designers can turn ideas into physical prototypes and revise them quickly. This allows for faster response to changes and improvements.

Success Stories and Application Examples

To illustrate the diverse possibilities of 3D printing in product development and prototyping, let’s take a look at some inspiring success stories and specific application examples:

- Tesla Motors:

The renowned electric car manufacturer Tesla extensively utilizes 3D printing to create prototypes of vehicle parts. This significantly expedites the development process, enabling the company to bring innovative electric vehicles to market faster. - Nike:

Sportswear manufacturer Nike has employed 3D printing to develop custom shoe soles for athletes. These soles perfectly adapt to the individual needs and running styles of athletes. - 3D-Printed Prosthetics:

In the medical field, 3D printing has revolutionized the production of customized prosthetics. Companies like Open Bionics manufacture 3D-printed prosthetics that are both affordable and functional. - Aerospace Industry:

The aerospace industry uses 3D printing to produce complex components for rockets, airplanes, and satellites, contributing to weight reduction and performance enhancement. - Architectural Models:

Architects use 3D printing to create detailed models of buildings and urban developments, facilitating the visualization and planning of construction projects.

Sustainability

3D printing has not only transformed the way products are developed but also has positive effects on the environment. A key aspect is sustainability, promoted by 3D printing. Compared to traditional manufacturing methods, 3D printing significantly minimizes material waste, using only the material necessary for the product. This efficient use of resources not only contributes to cost savings but also reduces the ecological footprint of production.

Another step toward sustainable 3D printing involves the development of environmentally friendly materials. Research and innovations in this area aim to create materials that are not only effective in the printing process but also biodegradable or recyclable. These advances are crucial for further minimizing the environmental impact of production and establishing 3D printing as an eco-friendly manufacturing option.

Future of 3D Printing in Product Development

While 3D printing technology has already made significant strides, there are still many areas where innovations are expected. Here are some aspects of future development:

- Material Innovation:

Researchers are continually working on developing new 3D printing materials with improved properties, potentially expanding the range of applications significantly. - Multi-Material Printing:

3D printing with multiple materials simultaneously allows for the creation of products with different properties in a single printing process. This could simplify the manufacturing of complex assemblies. - Bioprinting:

In the medical field, efforts are underway to develop biological tissues and organs using 3D printing. This could revolutionize transplant medicine in the future. - Nanoprinting:

The use of nanotechnology in 3D printing opens the possibility of manufacturing products with exceptional precision, particularly crucial in the electronics industry. - Artificial Intelligence and Simulation:

The integration of AI and simulation into the 3D printing process could further enhance the design and optimization of products. - Decentralized 3D Printing:

With the increasing availability of 3D printers, companies could decentralize their production and manufacture products closer to the customer. - Sustainability:

Sustainable materials and processes in 3D printing could lead to more environmentally friendly production methods.

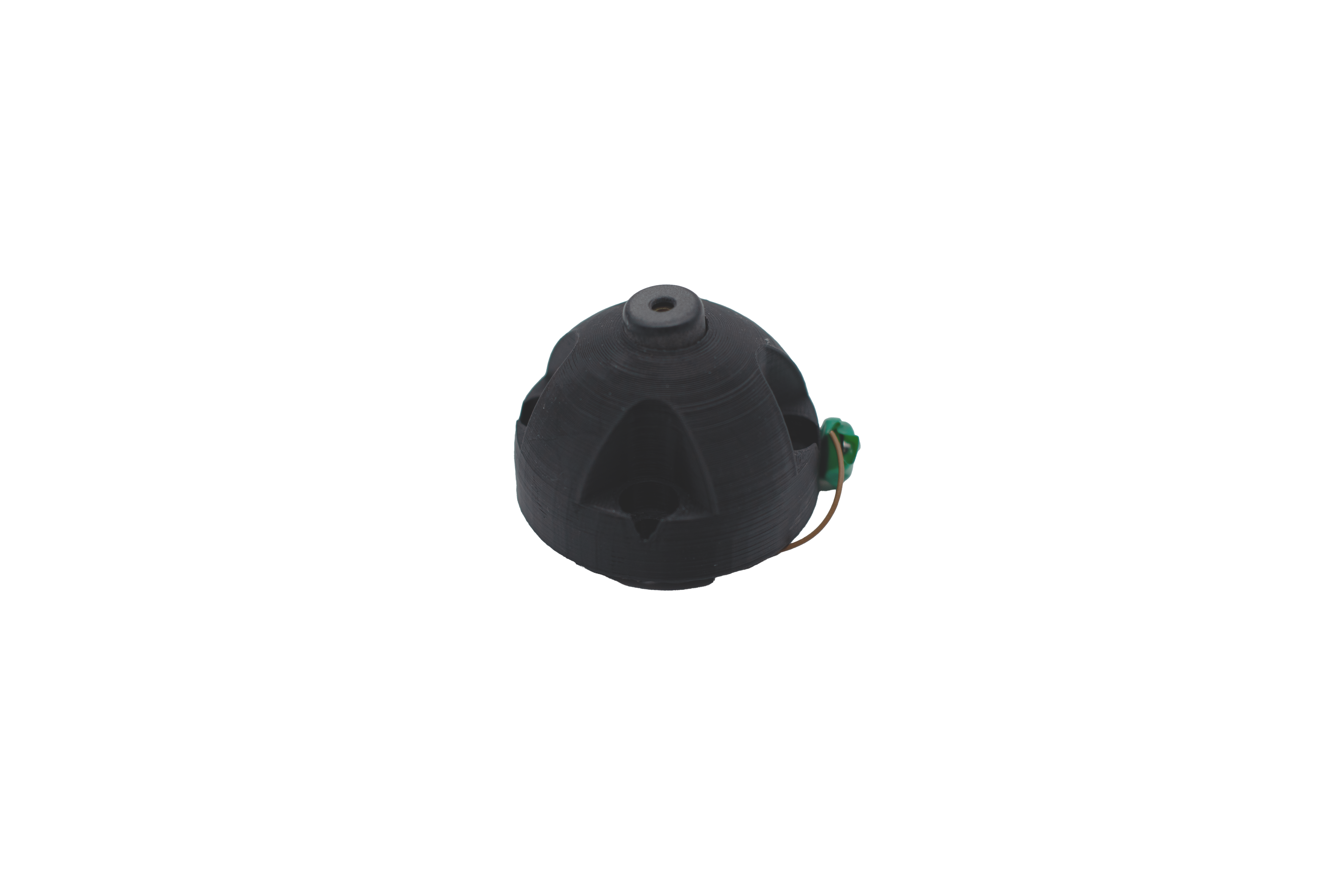

Prototyping and 3D Printing at ringbach

ringbach supports both prototype development and the creation of a production part that may later be manufactured, for example, through injection molding. Additionally, we provide consultation in the areas of drive and automation technology, as well as sensor and control technology.

Our manufacturing capabilities at the Landshut location include several FDM printers (Fused Deposition Modeling) in different sizes (component size up to 1000 x 1000 x 1000 mm). The components are printed according to your requirements (dimensions, material, color, etc.) and can be post-processed and refined if desired. We then ship the components directly to you.

For more information, feel free to read one of our >> Case Studies << or inquire >> here <<at any time.

Conclusion

3D printing has revolutionized product development and prototyping. In this article, we have explored the diverse applications and advantages of 3D printing. From accelerated prototyping to customized product manufacturing, this technology offers tremendous possibilities.

Companies that efficiently harness 3D printing and adapt to future developments will become more competitive and innovative. Ongoing research and development promise exciting advancements. Welcome to the future of product development and prototyping.

Sources: