Air filtration and depth filtration

- No Comments

The quality of the air we breathe is of fundamental importance to our health and well-being. Whether we are in our own homes, at the workplace, or in public places, clean air is an essential prerequisite for a healthy life. In this article, we aim to delve deeper into two critical concepts that contribute to improving the air we breathe: air filtration and depth filtration.

What is Air Filtration?

Air filtration is a fundamental process for enhancing air quality by removing impurities, pollutants, and particles from the air. This process is achieved through the use of specially designed filters or filter media capable of effectively capturing and retaining harmful substances.

The main objectives of air filtration are:

- Particle Removal:

Air contains a variety of particles of different sizes and compositions, such as dust, pollen, smoke, bacteria, and viruses. Air filters are designed to filter these particles from the air, thus purifying the breathing air. - Pollutant Removal:

Air can also contain various gaseous pollutants, including chemical vapors, odors, and allergens. Air filters may contain special media that adsorb or chemically neutralize these pollutants. - Improvement of Air Quality:

Air filtration helps improve indoor air quality by reducing allergens, eliminating unpleasant odors, and protecting people’s health.

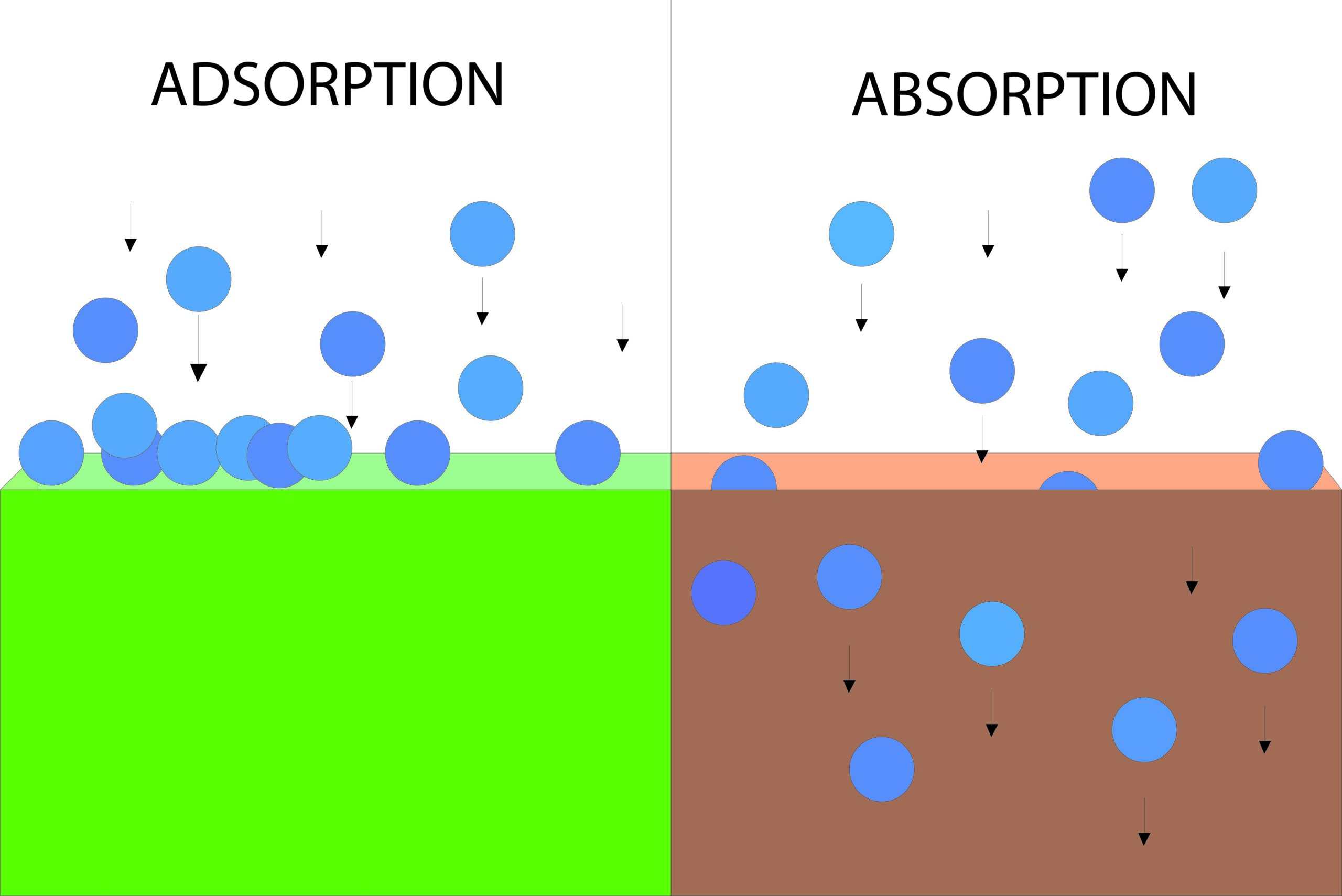

Air filters are found in various applications, including heating, ventilation, and air conditioning (HVAC) systems, air purifiers, automobiles, industrial facilities, and even medical devices. They can be classified in various ways based on their efficiency and application. The efficiency of air filters is often indicated by their Minimum Efficiency Reporting Value (MERV) rating, which indicates how well a filter retains particles of different sizes.

The Forces Behind Filtration

Air filtration relies on a fascinating array of physical principles and forces that drive it. Here are some of the main forces that compel air to confront the filters:

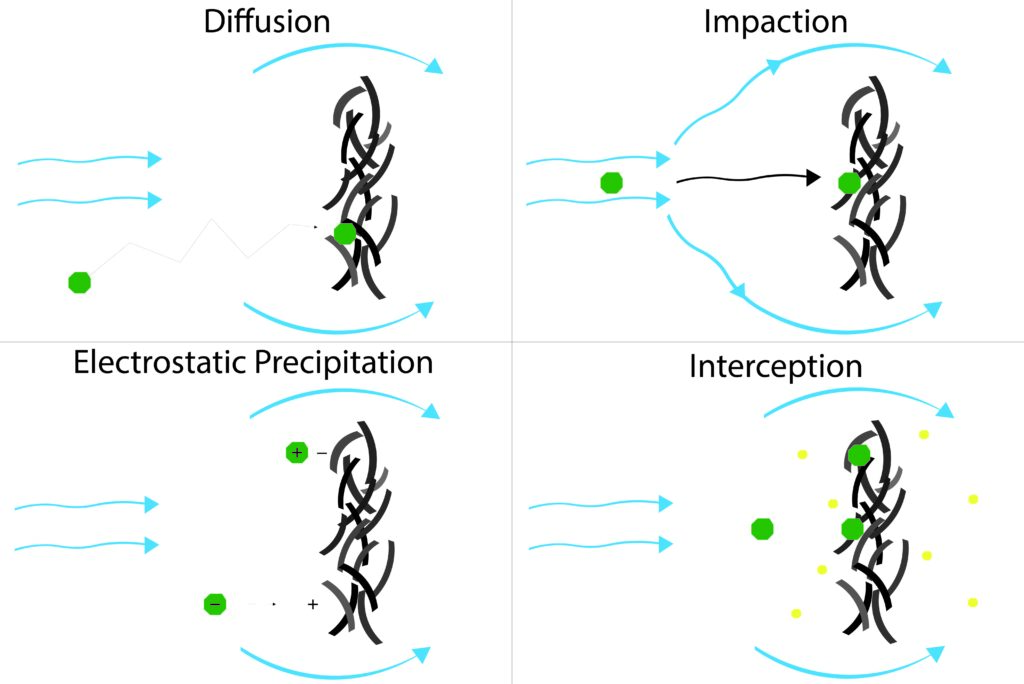

- Diffusion:

Diffusion is the process by which particles, due to their random motion in all directions, gradually spread evenly throughout space over time. This causes particles near the filters to diffuse toward the filters due to their random motion and eventually become trapped. - Impaction:

In impaction, particles in the air move in a straight line and have inertia due to their mass. This causes them to collide with and adhere to the filter material. - Electrostatic Precipitation:

In electrostatic air filters, particles are attracted and bound to the filter by electrostatic forces. This occurs through the interaction between charged particles and the charged surfaces of the filter. - Interception:

Interception occurs when particles are intercepted by filter fibers based on their size and shape as they pass through the air. This happens when particles pass close to the fibers.

(See Figure 1)

Why Is Air Filtration So Important?

Air filtration and its significance extend across numerous aspects of life. Here are some examples where air filtration plays an essential role:

- Health and Well-being:

The air we breathe directly impacts our health. Air filters play a crucial role in removing harmful particles such as pollen, dust, bacteria, and viruses from the air, reducing the risk of respiratory diseases, allergies, and other health problems, especially in individuals with respiratory issues or allergies. Additionally, clean air contributes to an overall pleasant living environment, promoting well-being and productivity by making people feel fresher and more energetic. - Environmental Protection:

Air pollution is a significant environmental issue. Filtering air in industrial processes and vehicles can reduce harmful emissions, leading to reduced environmental impact. - Pharmacy and Food Safety:

In certain industries like food and pharmaceuticals, air filtration is critical to ensure product quality and purity. Air filters prevent contamination of food and medications by harmful particles and microorganisms. - Energy Efficiency:

Air filtration can also contribute to improved energy efficiency. In heating, ventilation, and air conditioning (HVAC) systems, clean filters ensure that the equipment operates efficiently, as it is not hindered by clogged or dirty components. - Medical Protection:

Air filtration helps remove disease-causing germs like viruses and bacteria, protecting both patients and medical staff from infections. This is particularly crucial in operating rooms, intensive care units, and laboratories to maintain health and ensure accurate medical tests and treatments. Air filtration minimizes the risk of infection and ensures the integrity of medical procedures. - Allergen Control:

Air filters remove pollen, pet dander, and other allergens from the air, helping reduce allergic reactions and enhance well-being.

What Is Depth Filtration

Depth filtration is a specialized method for removing particles and pollutants from the air based on the use of a porous filter medium. In this process, particles penetrate the filter medium and become trapped within it, thereby purifying the air of harmful contaminants. This is especially important in environments with stringent cleanliness requirements.

How Does Depth Filtration Work?

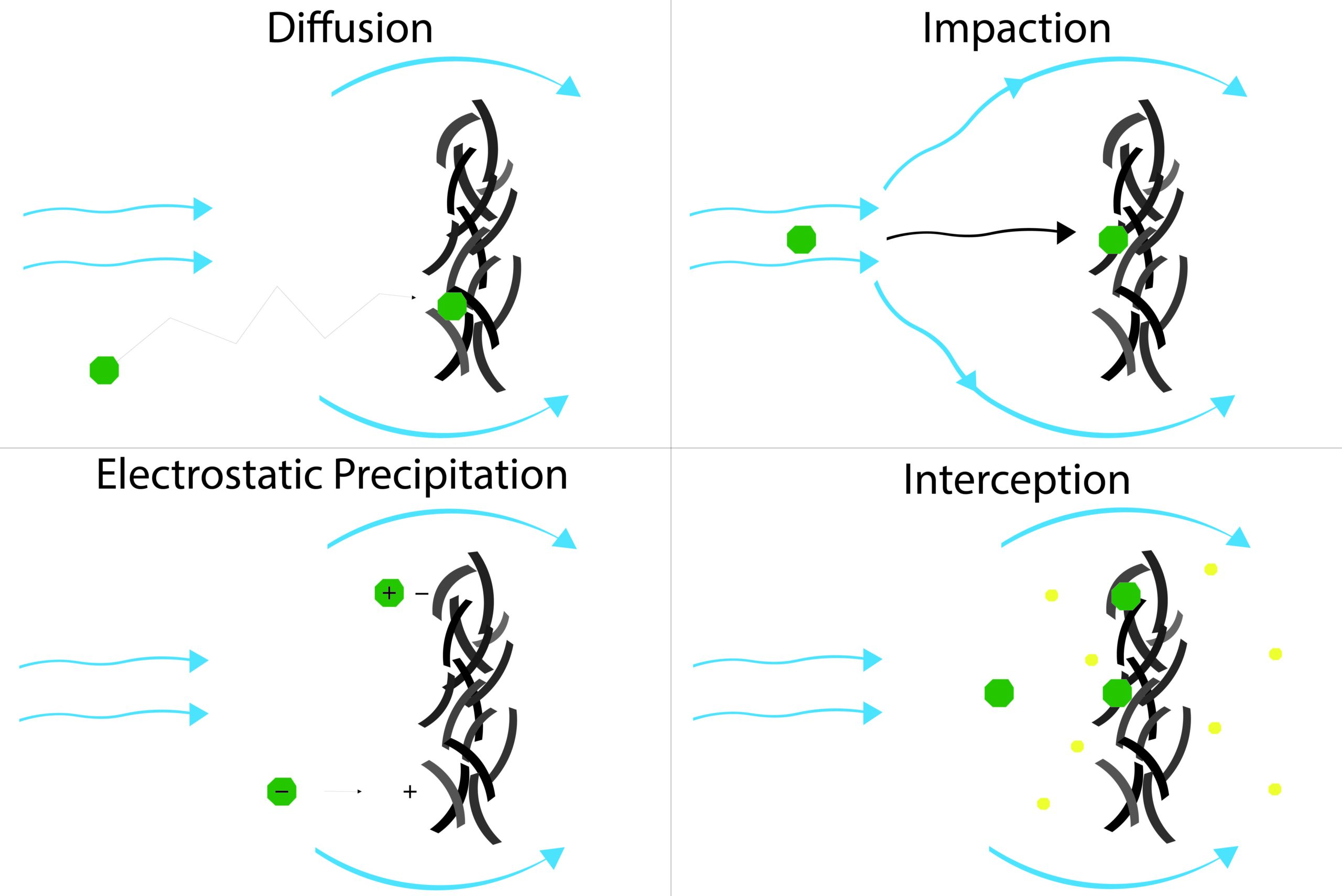

Depth filtration is an advanced air purification method that uses a special porous filter medium. This filter medium consists of a network of pores and channels designed to effectively capture particles and pollutants. Unlike conventional surface filtration, where particles adhere to the filter’s surface, depth filtration allows deeper penetration of particles into the filter medium.

Here, the principle of absorption comes into play. Absorption involves the uptake and chemical binding of gaseous pollutants and chemicals by the filter material. This occurs due to the affinity between the pollutants and the surfaces of the filter material. The pores serve as carriers for these absorption processes, effectively removing harmful gases and chemicals from the air.

Depth filtration can also utilize adsorption, where particles adhere to the surface of the filter material. This can occur in addition to absorption and contribute to efficient removal of particles from the air.

The combination of adsorption and absorption in depth filtration allows for thorough removal of particles and gaseous pollutants from the air. This process finds application in environments where the highest standards of air purification are required, such as in cleanrooms in the electronics industry or in the production of pharmaceutical products. Effective depth filtration ensures that the air in such environments is extremely pure and free of contamination.

Standards for Air and Depth Filtration

Air Filtration:

- ISO 16890: Classification of Air Filters:

ISO 16890 is an international standard that standardizes the classification of air filters and specifies the efficiency of particle removal across different sizes. This norm provides a more precise method compared to the outdated DIN EN 779. Air filters are categorized into various groups based on their ability to retain particles with specific diameters. This classification allows users to choose the appropriate filter for their specific requirements, ensuring air quality in various environments. - ISO 29463: High-Efficiency Air Filters (HEPA and ULPA):

ISO 29463 pertains to high-efficiency air filters such as HEPA (High Efficiency Particulate Air) and ULPA (Ultra Low Penetration Air). These filters are crucial in environments where the highest purity standards are required, such as cleanrooms in the electronics or pharmaceutical industries. The standard establishes testing procedures to determine the separation efficiency of these filters and ensures they meet the required standards. - ISO 10121: Testing of Molecular Filters

ISO 10121 addresses the testing or test procedures for molecular filter media and molecular air filters against various gases. The norm establishes minimum requirements for molecular filters in ventilation systems, serving as a measure of the efficiency of molecular filters. ISO 11155: ISO 11155 is an international standard that pertains to the labeling of medical gases in pressure receptacles for medical applications. It establishes requirements for the labeling, transportation, and handling of medical gases. In the context of medical care, ISO 11155 is crucial for ensuring the safety and reliability of medical gases and facilitating standardized handling.

DIN 71460: DIN 71460 is a German standard focusing on the quality of activated carbon filters for the air in vehicle interiors. It sets requirements for the filters to ensure effective reduction of unpleasant odors, harmful gases, and particles. The standard ensures that activated carbon filters in vehicles withstand standardized testing procedures, thereby improving air quality in the vehicle interior. This is particularly important to ensure the comfort and health of occupants, especially in urban areas with elevated air pollution.

EN 149: EN 149 is a European standard that concentrates on particle-filtering respiratory protective devices, including particle-filtering half masks. It specifies the minimum requirements for respiratory protective devices designed to protect against solid particles. This standard is of great importance, especially in environments where workers need protection from harmful particles, aerosols, and pathogens. EN 149 ensures that respiratory protective devices meet specific standards and provide effective protection, thereby safeguarding the health of users.

Depth Filtration:

- ISO 11171: Particle Count and Size Distribution in Hydraulic Fluids:

In hydraulic systems, the quality of hydraulic fluid is of paramount importance. ISO 11171 specifies testing procedures to determine particle count and size distribution in hydraulic fluids. This is particularly crucial for monitoring the performance of filtration systems in hydraulic systems, ensuring they effectively filter out particles. - ISO 16889: Filter Separation Efficiency and Pressure Loss in Hydraulic Fluids:

ISO 16889 outlines testing procedures for determining the separation efficiency of filters and pressure loss in hydraulic fluids. This standard is essential for evaluating filters in hydraulic systems to ensure they meet the required standards and provide effective filtration. - ISO 2942: Compatibility of Hydraulic Fluids with Filter Elements:

ISO 2942 addresses the compatibility of hydraulic fluids with filter elements. This standard ensures that the filter materials and elements used are not adversely affected by the hydraulic fluid, ensuring the longevity and efficiency of the filters.

Conclusion

The increasing world population and the associated growing demand for fresh air, along with rising emissions on our planet, pose significant challenges. In this era of environmental awareness and health care, air filtration and depth filtration have become indispensable allies. These technologies are the answer to the rising demand for clean, healthy air indoors and in industrial processes. They serve as shields against harmful particles and pollutants that threaten our health and burden the environment. Air filtration and depth filtration are the keys to a future where clean air is equally accessible to all people on our planet. It is our responsibility to use and further develop these technologies to ensure a sustainable and healthy future for generations to come.

Sources: