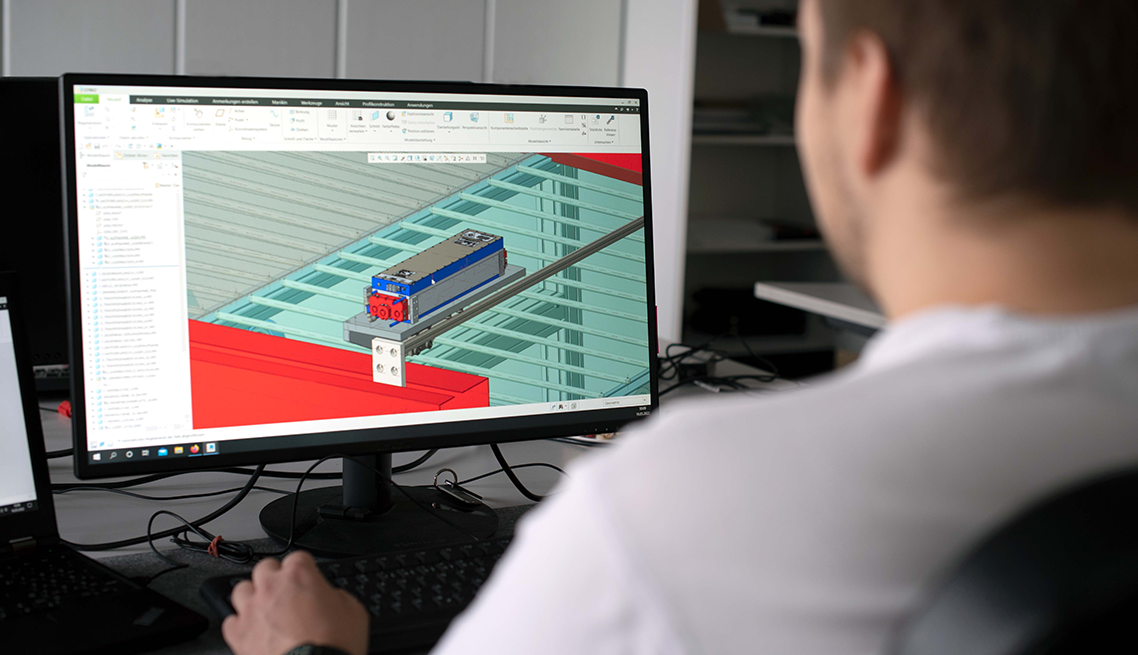

Construction (CAD)

Reduce costs, improve cycle time, increase productivity. To achieve these goals together with you, we take a methodical and organized approach to design. With the help of CAD designs, we can influence subsequent production in advance. Our goal is to bring innovative products to market together with you and to produce them economically in high-wage countries.

Advantages of 3D CAD design

To meet the demands of a rapidly growing world, the principle of the Digital Twin has become the industry standard. The Digital Twin created by 3D CAD design offers you several advantages:

An important advantage is the possibility to represent the final product three-dimensionally in digital format in advance. This allows the product to be validated and accepted before expensive tools and semi-finished products are ordered. This lowers development costs and significantly reduces the potential for errors.

All technical drawings relevant for manufacturing can be created from the 3D model with just a few mouse clicks.

Thanks to the material properties stored in the CAD program, FEM analyses can be carried out quickly and without major calculation effort, for example to check the deflection of load-bearing elements. Furthermore, installation space, weight and installation analyses can be carried out to ensure easy handling during final assembly.

Thanks to the CAD network, changes to components can be tracked via version creation. This makes the work processes more transparent and clearer. The changes are then transferred directly to the overall assembly.

Also not to be neglected is the time saved when using CAD programs for product development. These time savings can give you a significant competitive advantage later on the market.

Non binding request

At Ringbach, our engineers primarily use PTC Creo (formerly Pro/ENGINEER). Appropriate tools are utilized for quick sketches and prototyping (e.g., for 3D-printed parts).

The 3D models and drawings are stored securely in the cloud. In this way, all team members have access to the CAD-based models. This allows workflows to be parallelized. Such easy access to the models improves communication.

Simply send us a non-binding inquiry!