Neutralization of Electrostatic Charging

- No Comments

Electrostatic charging is an omnipresent phenomenon with significant implications for industry and daily life. From inconspicuous friction on a carpet to industrial processes, undesirable consequences can arise. This article focuses on the necessity and solutions for neutralizing electrostatic charging. Explaining from basics to modern methods, it elucidates how electrostatic charging occurs, its effects, applications, and future developments. The aim is to foster a better understanding of neutralization and highlight its crucial role in safety and product quality.

What is Electrostatic Charging?

Electrostatic charging is a physical phenomenon occurring when there’s an inequality in the distribution of electric charge within a material. This state arises from the transfer of electrons between two materials coming into contact through friction or separation.

How Does Electrostatic Charging Occur?

When two differently charged materials rub against each other, electrons transfer from one material to another. This process, known as the triboelectric effect, leads to charge separation: one material loses electrons and becomes positively charged, while the other gains electrons and becomes negatively charged. The triboelectric series determines which material donates or gains electrons based on its position in this series. The resulting charge remains localized on the surface of the materials, creating an electric field around them.

This electrostatic charging, arising from direct friction and the triboelectric effect, can have significant impacts in various environments and industries. From industry to daily life, undesired effects like attraction of dust particles, malfunctioning of electronic devices, or even damage to sensitive products can occur. Understanding these processes is crucial to minimize potential risks and effectively harness the effects of electrostatic charging in technological applications.

Methods of Electrostatic Charge Neutralization

Neutralizing electrostatic charging requires targeted measures to correct the imbalance in charge distribution. An effective method involves discharging charged materials through grounding. By contacting a conductive medium connected to the earth, excess electrons can dissipate, neutralizing the material.

Another approach to neutralization involves using conductive materials in processes and products. These materials facilitate controlled electron flow, minimizing the likelihood of charge accumulation and supporting continuous neutralization.

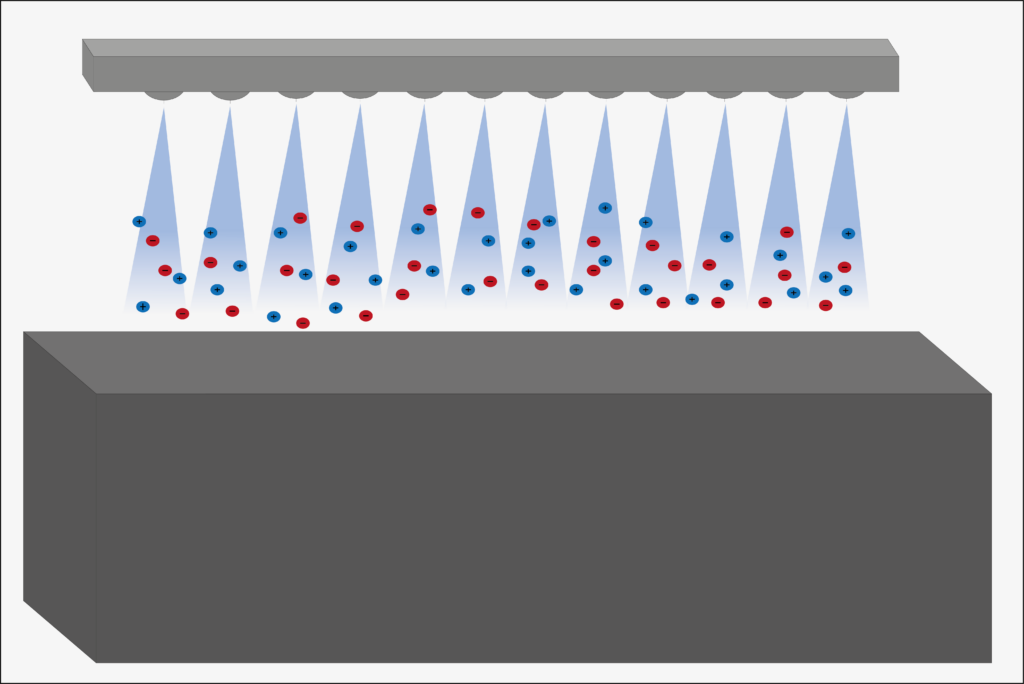

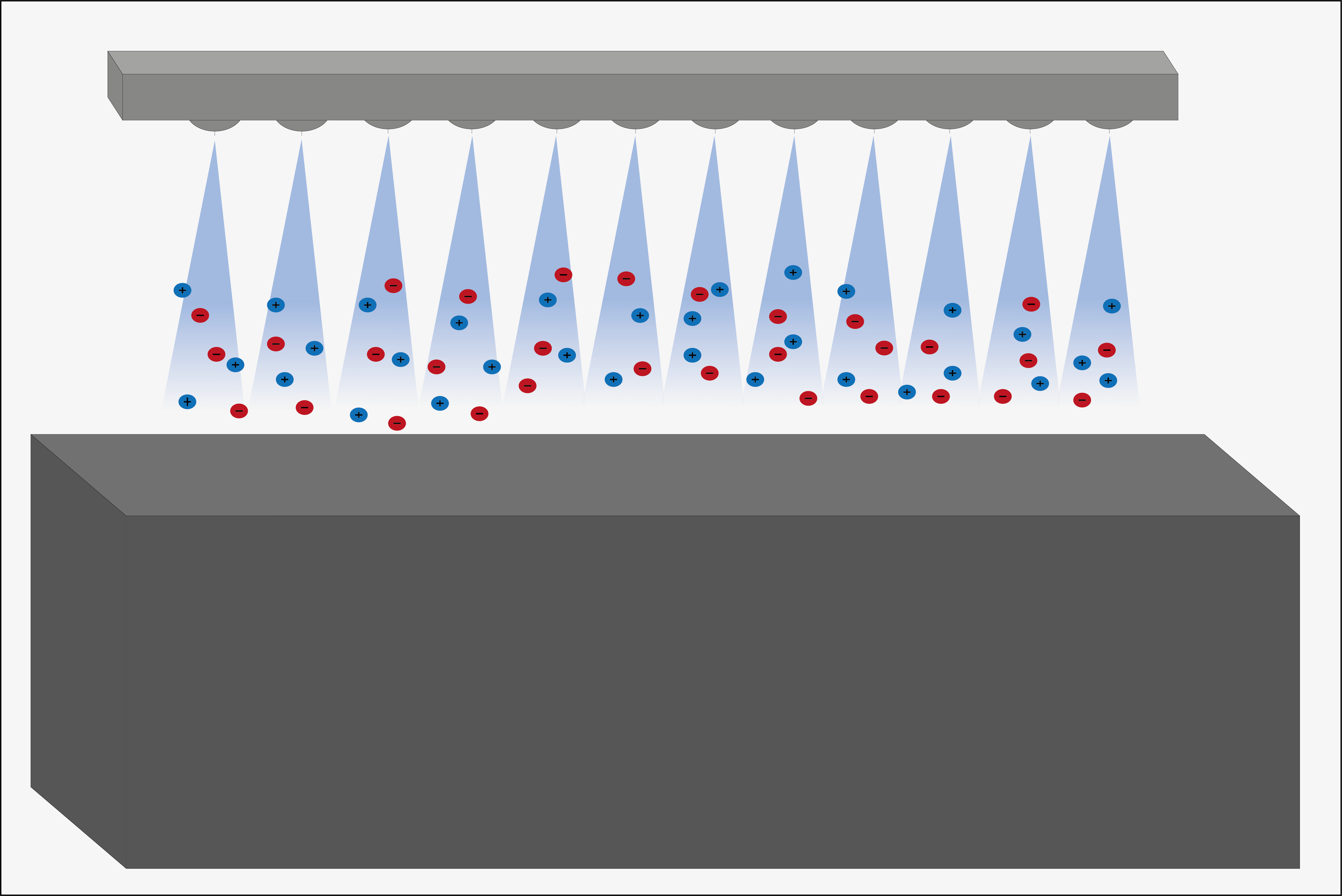

Furthermore, modern technologies like ionizers and specialized neutralization devices are employed to release ions selectively and neutralize electrostatic charges. These advanced methods enable precise real-time control and adjustment to effectively reduce electrostatic charges.

These measures for neutralizing electrostatic charging are crucial to avoid undesired effects like dust deposition, electronic malfunctions, or product damage, ensuring a safe and reliable working environment.

Applications and Importance of Neutralization

Neutralization of electrostatic charging plays a crucial role in various industries and environments, significantly impacting numerous sectors.

In the packaging industry, neutralizing electrostatic charging is vital to prevent electrostatic attraction between packaging materials and products, improving packaging quality and ensuring better handling.

In electronics production, sensitive electronic components are particularly susceptible to electrostatic damage. Precise neutralization is critical here to ensure safe production and high product reliability.

Additionally, in the printing industry, neutralizing electrostatic charging is essential to avoid unwanted printing effects and ensure precise print quality.

Therefore, the application of neutralization techniques is not only economically significant but also substantially contributes to enhancing product quality and ensuring operational safety across various industries.

Importance of Neutralization for Product Quality and Occupational Safety

Neutralization of electrostatic charging plays a crucial role in product quality and occupational safety across various sectors.

In terms of product quality, uncontrolled electrostatic charging can lead to dust deposition on products, compromising quality. Targeted neutralization creates a clean production environment, resulting in high-quality end products.

Moreover, neutralization of electrostatic charging is crucial for occupational safety, especially in environments dealing with explosive materials. Electrostatic charging can lead to hazardous discharges, posing risks to workers and production facilities. Neutralizing these charges minimizes these risks, ensuring workplace safety.

Implementing effective neutralization methods is therefore crucial not only to ensure product quality but also to protect workers and production facilities.

Examples of Effective Practical Applications

In semiconductor production, precise neutralization methods in industrial clean rooms are essential to prevent electrostatic damage to sensitive microchips. Electrostatic charging can impair the functionality of semiconductor components and lead to quality issues, necessitating consistent neutralization.

Similarly, in the chemical industry, especially in areas handling explosive substances, specialized neutralization methods are employed to minimize the risk of sparks and uncontrolled discharges. Targeted neutralization enhances workplace safety and significantly reduces the risk of potential hazardous situations.

Technological Developments and Future Outlook

Continued scientific progress presents promising prospects for new technologies and innovations in neutralizing electrostatic charging. Particularly, the integration of nanotechnology offers opportunities for more precise control over electric charges. Nanobased neutralization devices represent an advanced method to effectively prevent and neutralize electrostatic charging.

Furthermore, IoT (Internet of Things) applications are gaining importance. Connected sensors and systems enable real-time monitoring of electrostatic conditions. This proactive monitoring not only contributes to timely neutralization but also enhances the efficiency and safety of production processes.

Despite these advancements, challenges remain:

Especially sensitive environments such as in medical technology or aerospace require extremely clean and controlled conditions. Therefore, new technologies are being developed to eliminate even minimal electrostatic charging and ensure the integrity of sensitive systems.

Additionally, research efforts focus on developing materials with enhanced conductive properties. The aim is to create materials that are inherently less susceptible to electrostatic charging, further contributing to minimizing this phenomenon.

Everyday Examples and Recommendations

Everyday Examples:

- Clothing and Dryers:

Wearing synthetic clothing or removing laundry from a dryer can lead to electrostatic charging, causing garments to cling together or produce small electrical discharges. - Touchscreens and Electronics:

Electronic devices like smartphones and tablets can attract invisible fingerprints and dust particles due to electrostatic charging, impairing screen visibility. - Car Seats:

Getting in and out of a vehicle can generate electrostatic charging, especially in dry air. This may result in feeling a small electrical discharge when touching metal parts of the vehicle.

Recommendations for Avoiding Electrostatic Charging in Everyday Life:

- Antistatic Clothing:

Wear antistatic clothing, especially during activities that may lead to friction and charge separation. - Humidifier:

Using a humidifier can increase air humidity and reduce electrostatic charging. - Antistatic Cleaners:

Use antistatic cleaners for screens and electronics to minimize dust attraction.

Examples of Electrostatic Charge Neutralization in Everyday Life:

- Conductive Flooring:

In residential areas, conductive flooring can help minimize electrostatic charging. - Air Ionizers:

Using air ionizers in rooms can help neutralize charged particles and improve air quality. - Antistatic Handles:

During electronics repairs, use antistatic handles or wristbands to prevent electrostatic damage to sensitive components.

Health Aspects of Electrostatic Charging

The health effects of electrostatic charging on humans can be diverse. In the short term, direct contact with highly charged objects can cause mild shocks, typically harmless but problematic for individuals with certain medical devices like pacemakers. Some people also report skin irritations or an uncomfortable tingling sensation with excessive exposure to electrostatic fields.

Long-term health risks are less clearly defined, but concerns exist regarding the potential development of symptoms associated with electromagnetic hypersensitivity (EHS), such as fatigue, concentration issues, and headaches. Additionally, there is a risk to the functionality of medical implants, as electrostatic discharges can interfere with these devices.

To minimize these risks, preventive measures are crucial. These include ESD (Electrostatic Discharge) protection devices in vulnerable environments, educating and training employees about the risks of electrostatic discharges, and implementing specific precautions for individuals with medical implants. Such strategies reduce the risk of health impacts from electrostatic charging and ensure safe handling.

Applications at ringbach:

At ringbach, the topic of electrostatic discharge plays a significant role in the development of nonwoven fabrics. Specifically, according to the ISO 11155-1 standard for cabin filters in cars and trucks, it is required that the cabin air filters undergo testing for electrostatic discharge. One method for this testing involves immersing the filter in isopropanol alcohol. This discharge simulates potential aging of the filter due to extended storage and serves to assess the electret effect during filtration.

Find out more about filtration >> here <<.

Conclusion

Electrostatic charging is an omnipresent phenomenon with diverse impacts on our daily lives and various industries. Neutralizing this effect is crucial for ensuring product quality, making work environments safer, and preventing potential damage to electronic devices. The diverse methods of neutralization, from grounding to advanced ionizers, provide effective solutions for various applications. With increasing awareness of electrostatic charging and technological advancements, the future of neutralization will be shaped by further innovations and sustainable solutions. AI and sustainability will also play significant roles in advancing these applications.

Sources: