Material processing with the laser

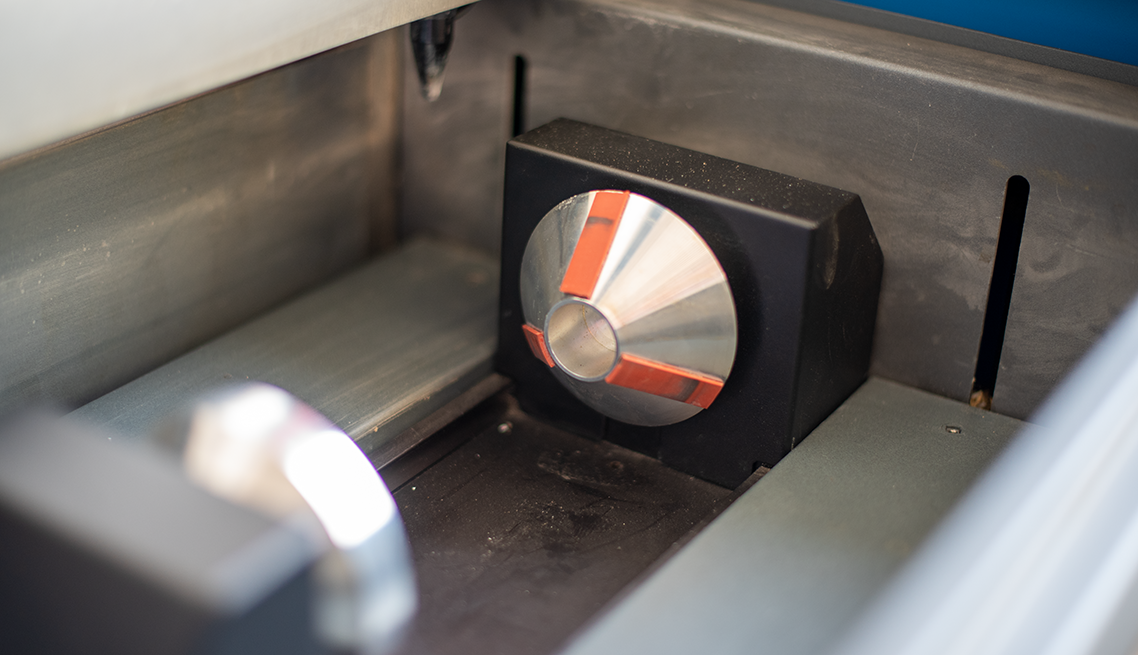

A laser can be used in a variety of ways. With the help of a laser cutting system, it can be used for cutting, welding, drilling or engraving. Laser cutting in particular brings all the advantages of the laser to bear. A bundled laser beam serves as a cutting tool during processing, which is generated by means of gases or crystals. This intense laser beam is amplified by a line system like a burning glass and focused precisely on a small area of the workpiece, creating a high energy density at this point. As a result, the material melts or vaporizes at this point and the cutting process begins.

Advantages of laser processing

The processing of materials with the laser offers a number of advantages over conventional processing methods. The most important ones from our point of view are listed below.

With the aid of a laser, the materials can be processed without contact and thus with high precision (standard +/- 0.1mm). Local heating also protects the material and results in very small cutting gaps.

The laser can cut a wide variety of different materials safely and with high quality, such as steel, aluminum and stainless steel to non-metallic materials such as plastic, glass, wood or acrylic.

Complex, filigree contours can be cut precisely, smoothly and without burrs, and time-consuming post-processing is no longer necessary in most cases. Therefore, laser cutting is one of the most economical and flexible processes today.

When processing with the laser, the edges are directly sealed by the local heat generated. This is particularly interesting when processing textiles and natural products.

The laser processing method allows products to be individualized and refined at comparatively low cost.

Non-binding request

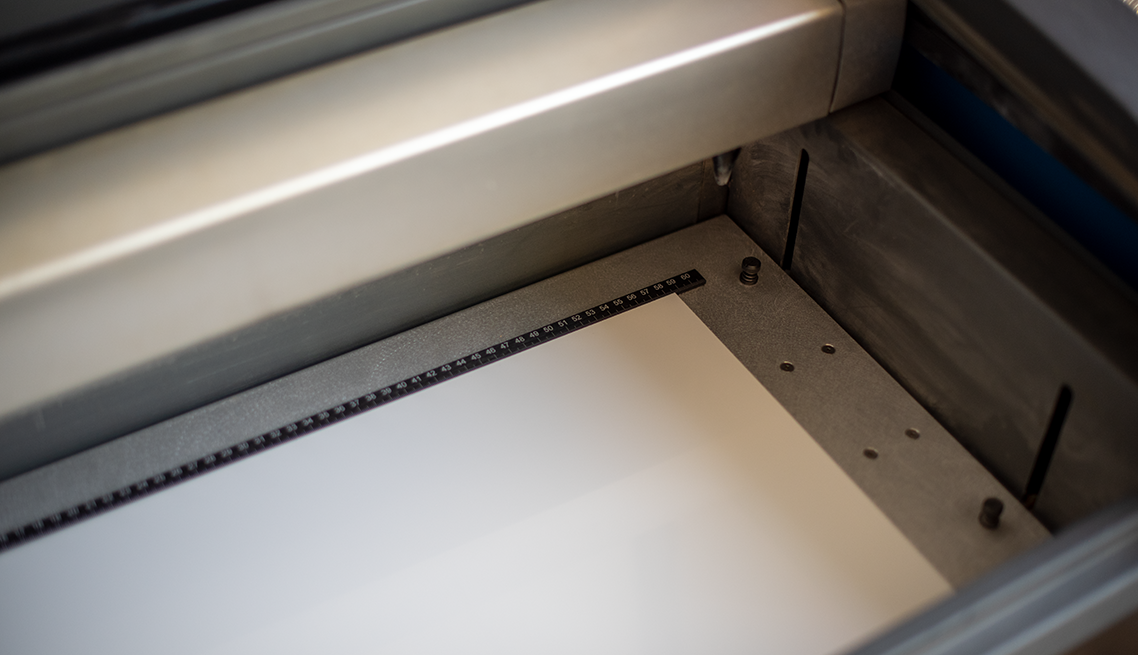

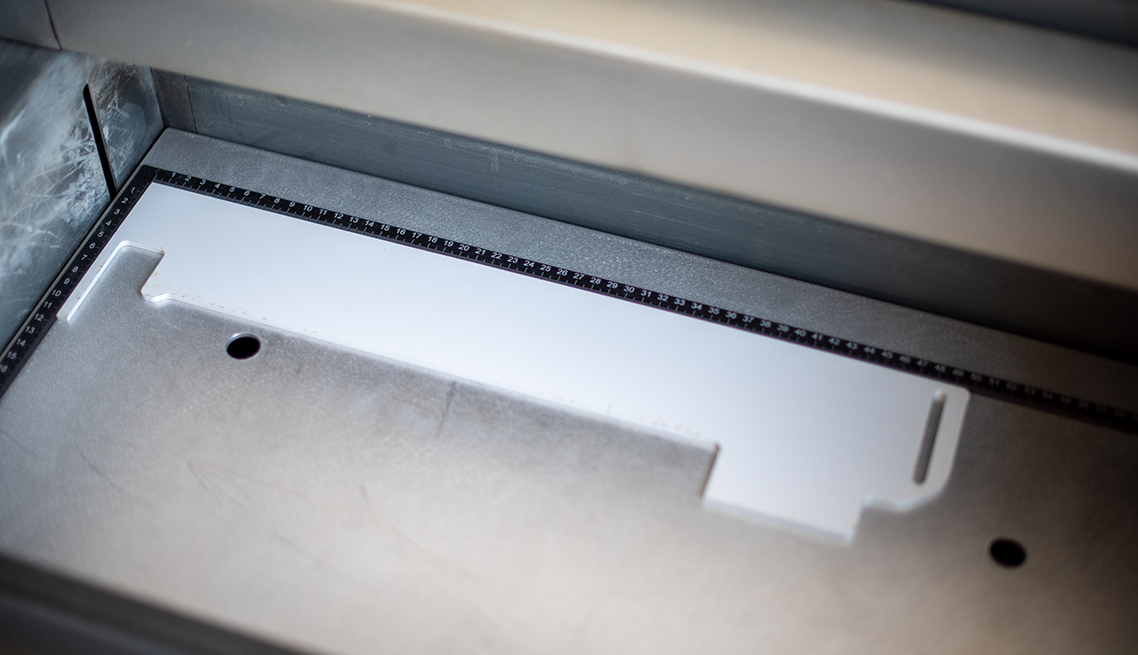

One of our services here in Landshut is laser processing. The machine portfolio includes a laser cutting machine of the Universal Laser Systems brand (600 x 300mm processing area) on which a wide variety of materials can be cut and individually engraved.

Just send us a non-binding inquiry!