Nonwoven – Everything you should know

- No Comments

Nonwoven fabric serves diverse purposes as a versatile and useful material. Here at ringbach, we engage in both the production of nonwoven fabric and its integration into a variety of systems. Whether in the clothing industry, construction engineering, or even medical technology, nonwoven fabric is applied in a multitude of fields. But what is nonwoven fabric? What is it made of and how is it produced? And what makes it so special? As experts in this field, we at ringbach will provide you with an in-depth understanding of this fascinating material.

What is nonwoven fabric?

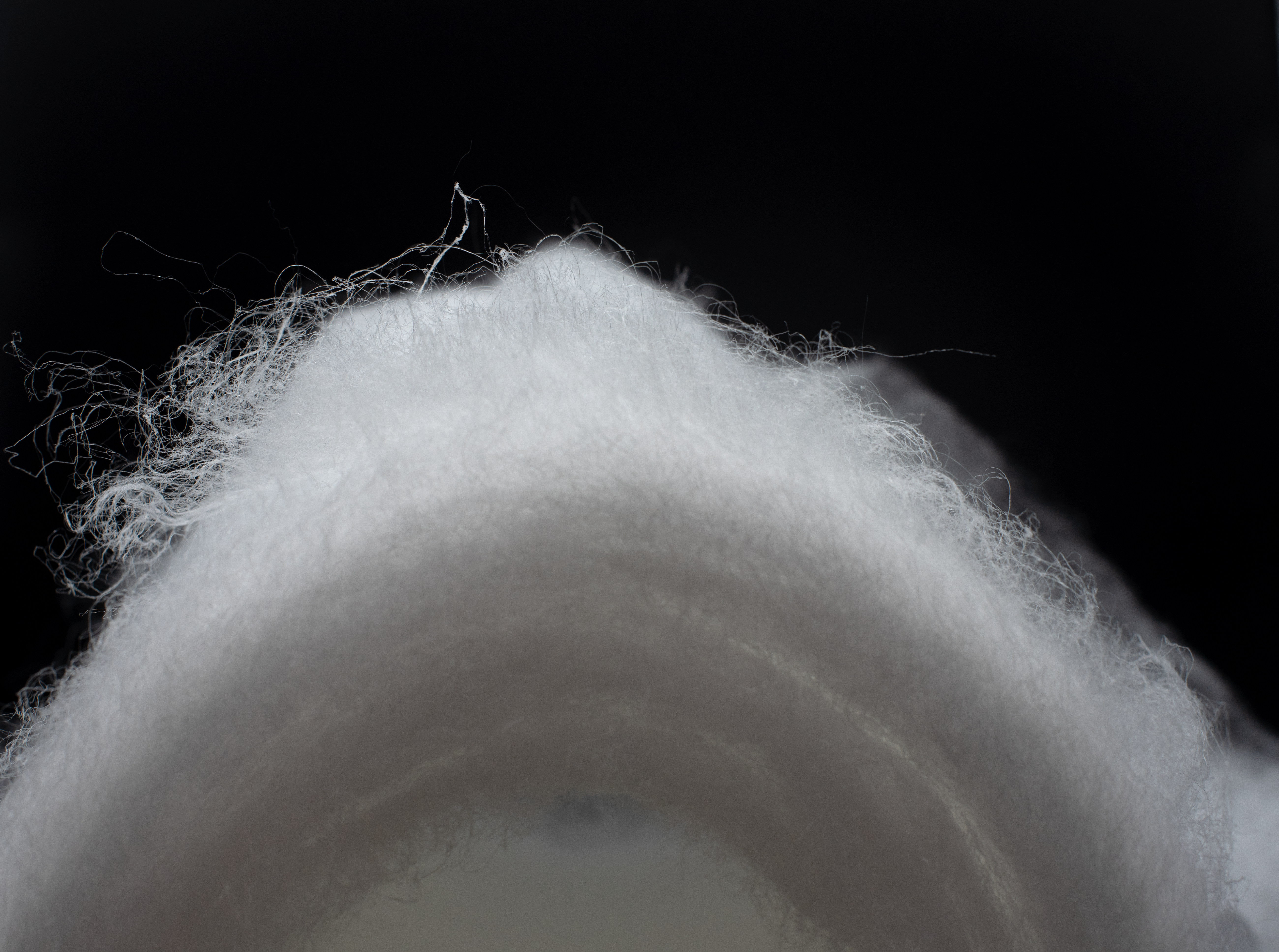

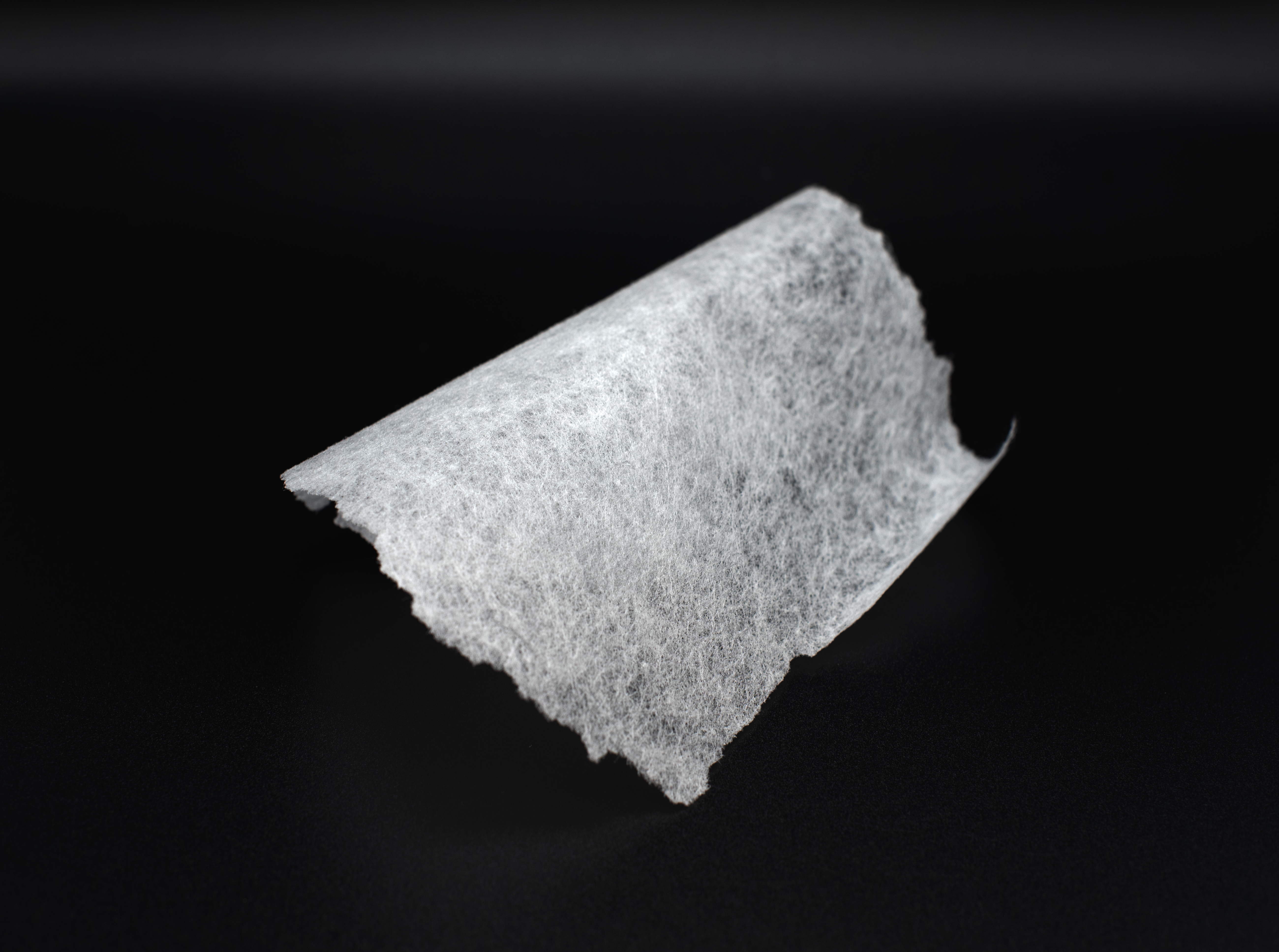

Nonwoven fabric, in simple terms, is a textile material composed of fibers processed into a loose, non-woven structure. During production, fibers are not woven in the traditional sense but are bonded together or, in some cases, thermally or mechanically solidified. Various natural or synthetic materials such as cotton, polyester, or viscose can be used as the base material.

What makes nonwoven fabric special?

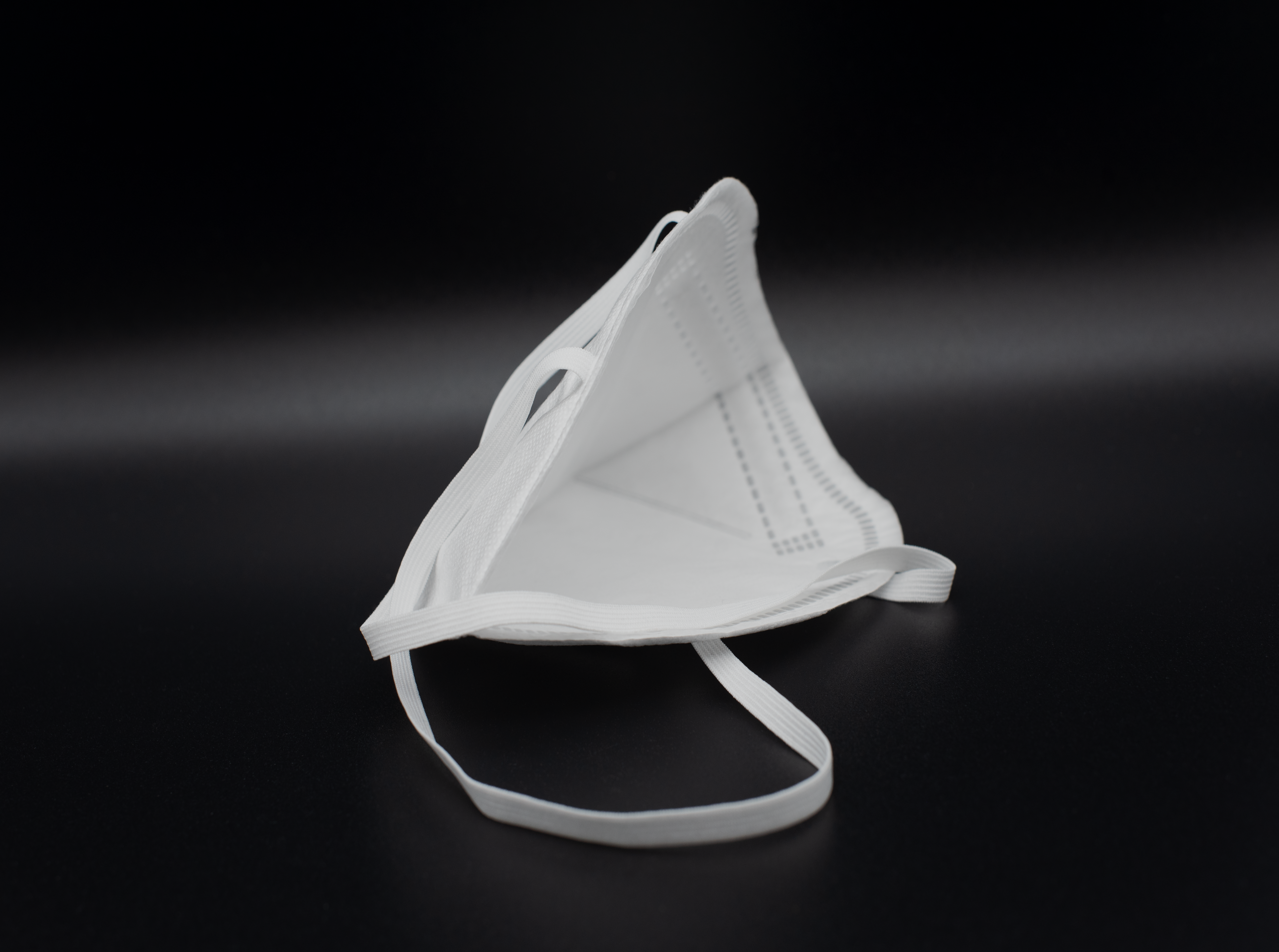

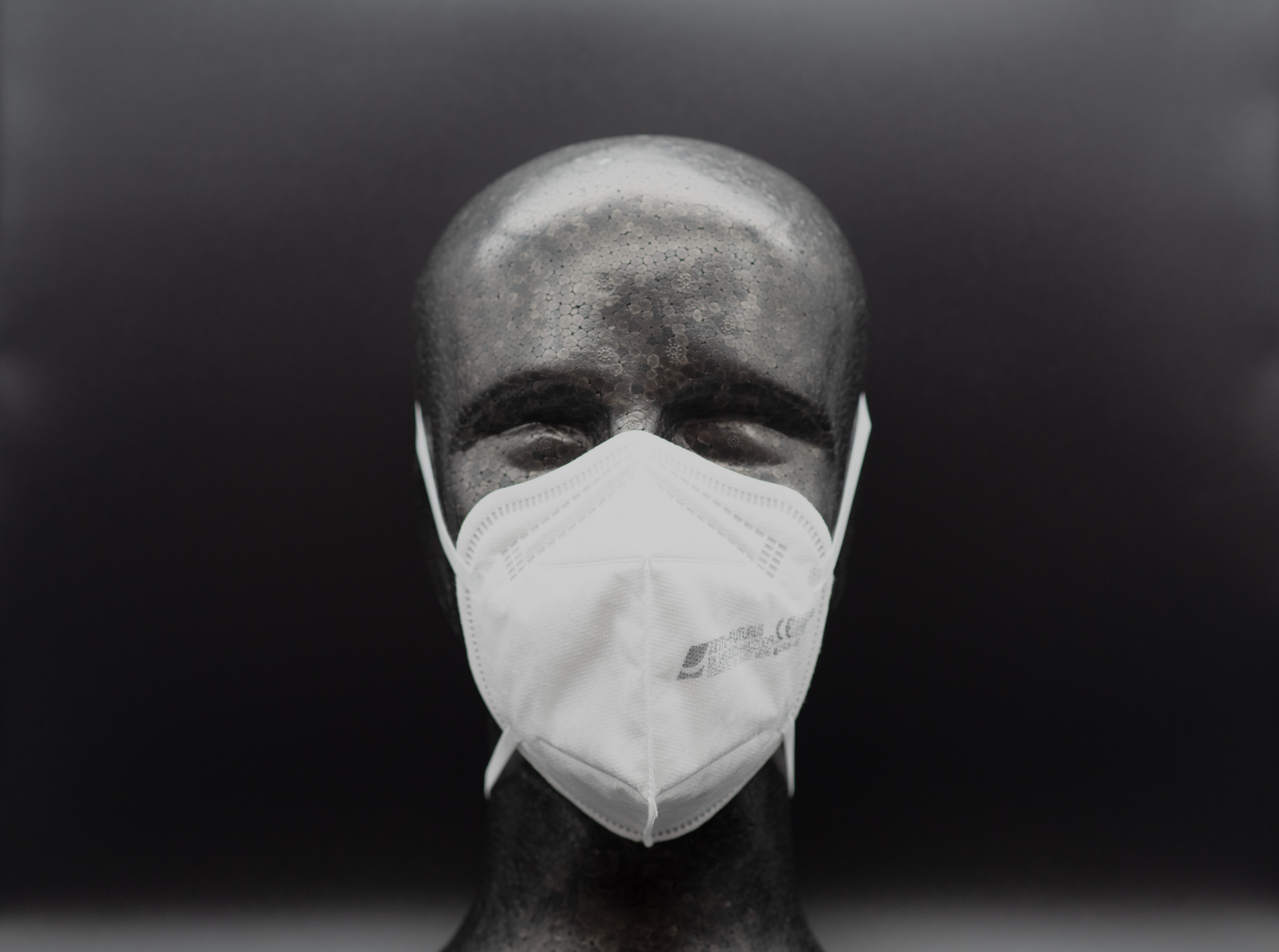

Firstly, nonwoven fabrics are generally much lighter than woven fabrics, making them ideal for applications where low weight is advantageous. For instance, in the packaging industry in the form of lightweight bags or fabric totes. Additionally, its soft and pleasant texture makes nonwoven fabric suitable for medical technology. For example, in FFP2 or FFP3 masks. The high air and water permeability of nonwoven fabrics find use in agriculture through air or water filters. Nonwoven fabric not only allows air and water to pass through but also filters out even the smallest particles and dirt. Due to its cost-effective and simple production, nonwoven fabric finds applications across numerous sectors. Moreover, the fact that nonwoven fabric can be produced from recycled materials highlights its excellence as an eco-friendly material, especially in mass production.

How is nonwoven fabric manufactured?

There are numerous methods for producing nonwoven fabric. In general, production can be divided into four steps:

- Fiber Preparation:

Raw fibers are selected and prepared. As mentioned earlier, various fibers can be chosen based on desired properties. Typically, the fibers are also decolored and cleaned during this stage. - Fiber Laydown:

Fibers are arranged to form a nonwoven fabric or fiber mat. Different approaches are used, including staple fiber, short staple fiber, and continuous filament laydown. Mechanical forces, water jets, or air flows are used to untangle and align the fibers. - Bonding:

Fibers are connected and stabilized. Different methods are employed here as well. In thermal bonding, fibers are melted and cooled, causing them to adhere to each other. Chemical bonding uses binders or adhesives to stick the fibers together. Mechanical bonding involves techniques like needle punching, ultrasonic bonding, or water jets. - Finishing:

Nonwoven fabric undergoes treatments to achieve specific properties. This can include shearing or cutting the fabric, applying coatings or laminations, and dyeing or printing for aesthetic purposes.

Advantages

As you’ve learned, nonwoven fabric possesses highly interesting qualities. Here’s a brief bullet-point list of the various advantages of nonwoven fabric:

→ Environmentally friendly

→ Cost-effective (requires minimal material for production)

→ Quick production (omitting weaving or knitting steps)

→ Versatility of applications

→ Lighter than woven fabrics

→ High absorbency

→ Dimensionally stable

→ Breathable

Fun Facts

Space Exploration: Nonwoven fabrics have been used in space exploration to enhance thermal insulation of spacecraft.

Aromatics: Nonwoven fabrics can be impregnated with fragrances and are often part of air fresheners or scented pillows.

Cold Insulation: Nonwoven fabrics can function similarly to insulation material, storing cold.

Air and Liquid Permeability: Nonwoven fabrics can be engineered to allow air or liquids to pass through, making them common in the filtration industry.

Manufacturing: Nonwoven fabric can be produced from unconventional materials, such as plant fibers, animal hair, or recycled clothing.

Agriculture: Nonwoven fabrics are frequently used in agriculture to cover soil, reducing moisture evaporation and weed growth.

Fire and Electricity: Nonwoven fabric can possess antimicrobial properties, as well as fire resistance and electrical conductivity.

Sound Absorption: Nonwoven fabrics can be used in sound-absorbing materials to enhance room acoustics.

Nonwoven fabric in medicine

One of the most crucial applications of nonwoven fabric is in the medical field. Due to its sterility-friendly nature, nonwoven fabric is essential to ensure sterility and hygiene for staff and patients. Many disposable products are primarily composed of nonwoven fabric, including surgical gowns, gloves, covers, and more. Furthermore, nonwoven fabric plays a significant role in respiratory protection. Nonwoven fabrics are vital in the production of FFP and N95 masks, which became well-known during the COVID-19 pandemic. FFP masks, in particular, protected a large portion of the population from particles and pathogens of the coronavirus. Nonwoven fabric provides materials for wound care and incontinence products, including pads, dressings, covers, bed protection, and more. Medical protective clothing often incorporates nonwoven fabrics. The filtering properties of nonwoven fabric are harnessed in various air and water filtration systems, as well as blood filtering systems. Nonwoven fabric is used in mattresses and cushions to prevent pressure ulcers. Its biocompatibility enables the use of nonwoven fabrics to reinforce tissues in surgery and serve as a foundation for tissue healing and growth.

What does the future hold for nonwoven fabric?

In the future, nonwoven fabric is expected to remain an essential material for us, whether in medicine, space exploration, or automotive manufacturing. Nonwoven fabric will continue to find utility in various applications and evolve alongside technology. As a biodegradable, lightweight, and durable material, there are already numerous research efforts involving nonwoven fabric. These include smart nonwoven fabrics embedded with sensors for monitoring health data. Nonwoven fabric is also integrated with nanotechnology to enhance properties like UV protection or water repellency. Additionally, nonwoven fabric is employed in lightweight construction, used in sectors such as aerospace and automotive industries to reduce weight while ensuring durability and insulation. The most impressive aspect of nonwoven fabric is its combination with 3D printing technology. Using a 3D printer, nonwoven fibers can be precisely arranged to create complex structures that meet specific requirements.

Conclusion

In conclusion, nonwoven fabric, as a versatile and rapidly producible material, is already finding applications in nearly all significant industrial sectors. With its environmental friendliness and cost-effective production, it’s likely that nonwoven fabric will continue to gain prominence in the global economy and become an indispensable material of the future. As one of the most promising materials, nonwoven fabric may soon replace several materials, especially in areas such as air and water purification filters, packaging paper and cardboard, various insulation materials for heat or sound, and much more. Nonwoven fabric is undoubtedly a material of the future, and its future importance should not be underestimated.