Functionality of a 3D printer

- No Comments

3D printers are one of the technical developments that have attracted a lot of attention in recent years. But how does a 3D printer actually work? These and other questions will be answered in this article.

Basic operation of a 3D printer

Not all 3D printing is the same, that much is already clear. A 3D printed component can be made using different processes. Each manufacturing process is characterized by specific materials and methods. But they all have one thing in common, they create a three-dimensional object by applying the material layer by layer. This manufacturing principle is also called additive manufacturing, generative manufacturing or rapid technology.

Before any printing can take place, however, a model must be created with the help of a CAD program. However, there are also 3D printing databases with millions of print templates. The file then simply transferred to the printer and printing can begin.

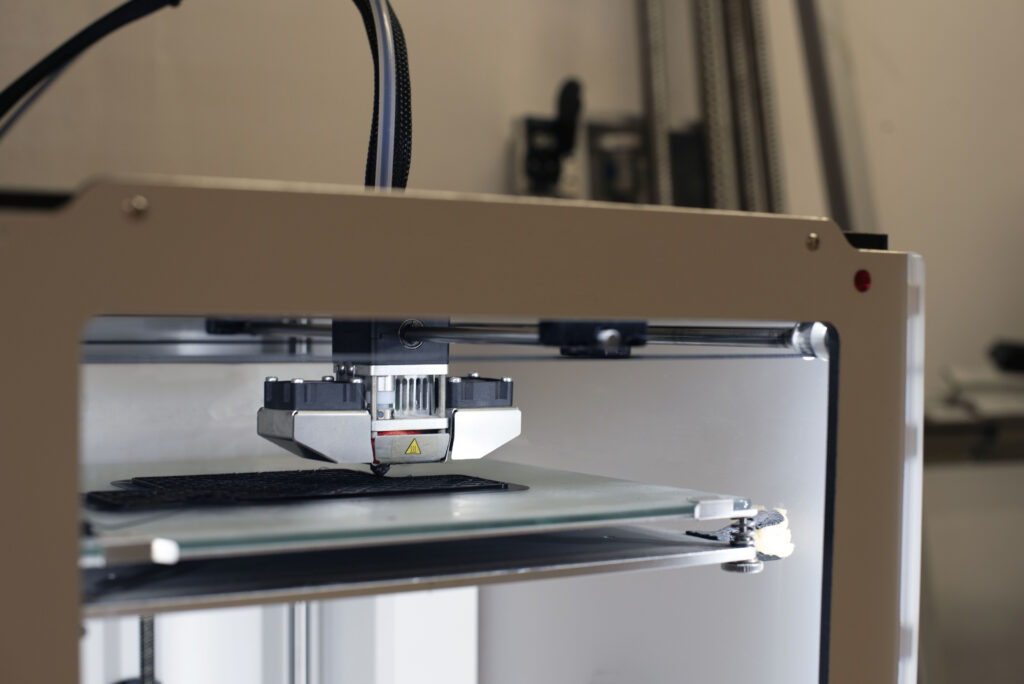

The hot end is one of the most important components of a 3D printer. In it, the solid plastic filament is liquefied and pressed into the nozzle (nozzle) with the help of the extruder motor. In combination with the movement of the print head, the nozzle thus travels along the required geometry and presses filament onto the print bed wherever the object requires material. The process is repeated until the 3D model is ready and can be removed.

In FDM printing or also SLA printing, the use of support structures is often necessary for production reasons, because filigree or overhanging structures must be supported in the printing process, because otherwise they could collapse. These must then be removed again later by post-processing.

3D printing technologies at a glance

FDM – Fused Deposition Modeling

It is the best-known process because it is easy to handle and is therefore used in almost all hobby devices. Almost any thermoplastic material can be processed with it. It works with the so-called “fused layer” process and is therefore similar to the way a normal inkjet printer works. The only difference is the movement in all spatial directions (X-Y-Z direction) whereby the printer builds up the 3D model layer by layer.

SLA – Stereolithography

This is also used in the hobby field. Here, the three-dimensional object is created by curing a UV-sensitive liquid (resin). To cure the individual layers one after the other, a DLP beamer is used, which shines from below through the UV-sensitive liquid and cures the resin at the focal point.

SLS – Selective Laser Sintering

In this process, the filament is not processed in filament form, but in powder form. In this process, the powder is applied in layers to a structural form and is bombarded with the aid of a powerful laser and fused at the points where the three-dimensional object is to be created.

Application areas of 3D printing technology

It can be said that 3D printing has made a name for itself in almost all areas of business and industry. Business and industrial sectors include the automotive industry, research and development, the bottle and cosmetics industry, and medical technology. Whether creating individual prototypes and models or one-offs and small batches, 3D printing can be the most economical process. In addition to plastic, many other materials can be used for 3D printing, such as fiberglass, carbon, PLA or even ABS.

Our production machines in the ringbach portfolio here in Landshut include a 3D printer. As a service, we offer the printing of 3D models. Using the additive manufacturing process, we can quickly and easily produce component samples for you from PLA or ABS.