automatica 2023 (engl.)

- No Comments

ringbach at automatica 2023. But what is the automatica exactly?

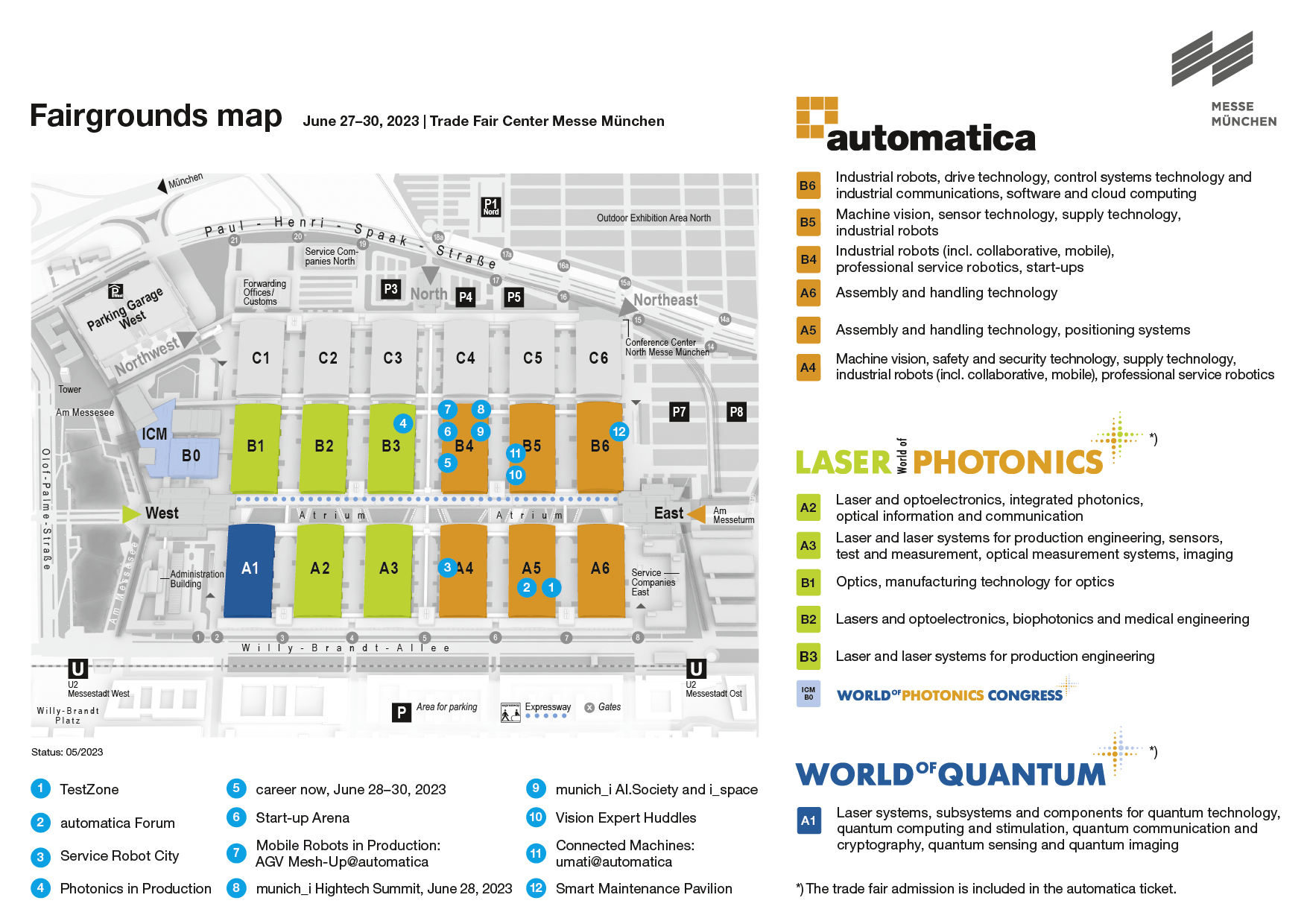

The automatica is the world’s leading trade fair for intelligent automation and robotics. It brings together industry, research, and politics for constructive and forward-thinking exchange. Moreover, it provides an overview of developments, topics, innovations, and solutions, ensuring orientation and investment security.

The automatica offers comprehensive insights into industrial automation, robotics, image processing, drive technology, and much more. Over 900 exhibitors from more than 40 countries showcase their services and products there. The automatica takes place every two years and is visited by more than 45.000 visitors from all over the world. In addition to numerouse lectures and workshops, the automatica is enriched by a multitude of live demonstrations of various robots and automation systems.

Robots are now an integral part of today’s industry and our everyday life. They are the basis for continuous progress and pave the way for a better future for us all.

We were there

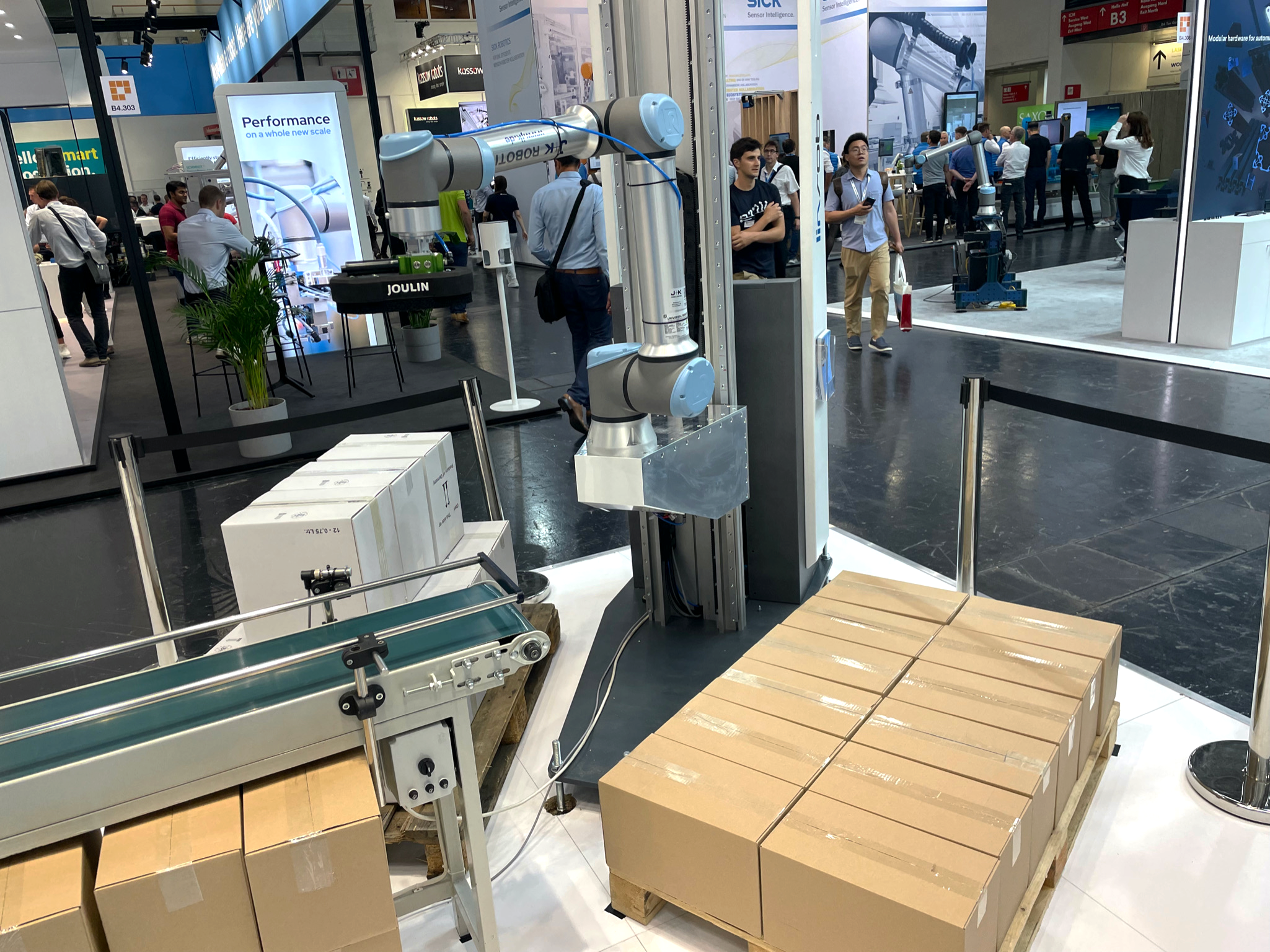

Together with linrob Automation, we headed to the automatica 2023 in Munich. In Hall B4, in the area of “Industrial Robots (collaborative and mobile)”, we assisted in the setup and commissioning of the exhibits. Some of these exhibits were pre-constructed and wired by ringbach.

Having humans and machines safely working in the same workspace was unimaginable for a long time, as the safety risk of working closely with a robot was simply too high. However, the so-called Cobots make this possible.

But what are Cobots?

Furthermore, Cobots have the so-called SLS (Safe Limited Speed), ensuring a defined transition from the operating speed in automatic mode to the reduced speed in setup mode.

Aren’t they just simply Robots?

In general, the difference compared to regular robots is that cobots (collaborative robots) lend a helping hand to humans, taking on individual tasks that involve constant repetition. A cobot can work both autonomously and in combination with humans. In this process, humans and machines can interact together in a confined environment. This is not the case with regular robots, as they operate in a more space-intensive and ‘indifferent’ manner. However, cobots can also be part of a fully automated robotic system. Frequently, cobots are used, for instance, in tasks such as loading production machines or in assembly processes.

And what benefits do cobots have?

In general it is to say that cobots are:

- space-saving

- can be used collaboratively

- have a fast Return on Investment (ROI)

- are generally cost-effective

- saving humans from monotonous and repetitive work

Our conclusion to the automatica 2023

Regardless of age, whether young or old, there was something for everyone at automatica 2023. Every visitor had the opportunity to glimpse into the future thanks to numerous exhibitors. At ringbach, we had not only many interesting conversations at automatica but also a lot of fun supporting linrob Automation. It was incredibly informative for us to witness how intelligent automation and robotics will continue to evolve hand in hand in the future and the direction in which the trends are heading.

One of the trends, among others, were palletizing solutions, which were showcased at the linrob Automation booth in cooperation with UR Universal Robots, Doosan, and Native Robotics.

Being part of automatica 2023 was a great pleasure for us, and we wholeheartedly recommend everyone to visit automatica 2025 to experience this breathtaking trade fair of the future for themselves.

Sources: