3D printer – The most important components explained

- No Comments

We already explained how a 3D printer works and the different printing techniques in one of our last posts. If you haven’t seen it yet, click on the link below this post and take a look. In this article we will talk about the most important 3D printing components.

Extruder

The extruder is one of the most important components of the 3D printer. It holds the filament in place and controls the amount that is fed into the hot end. The hotend is attached to the extruder and is the main part of the melting process. The extruders are equipped with a stepper motor that allows the filament to pass through. In addition, there is some kind of gearbox and a shaft with hob to keep the filament in place, sometimes a fan, a heat sink for better temperature control and finally the hotend.

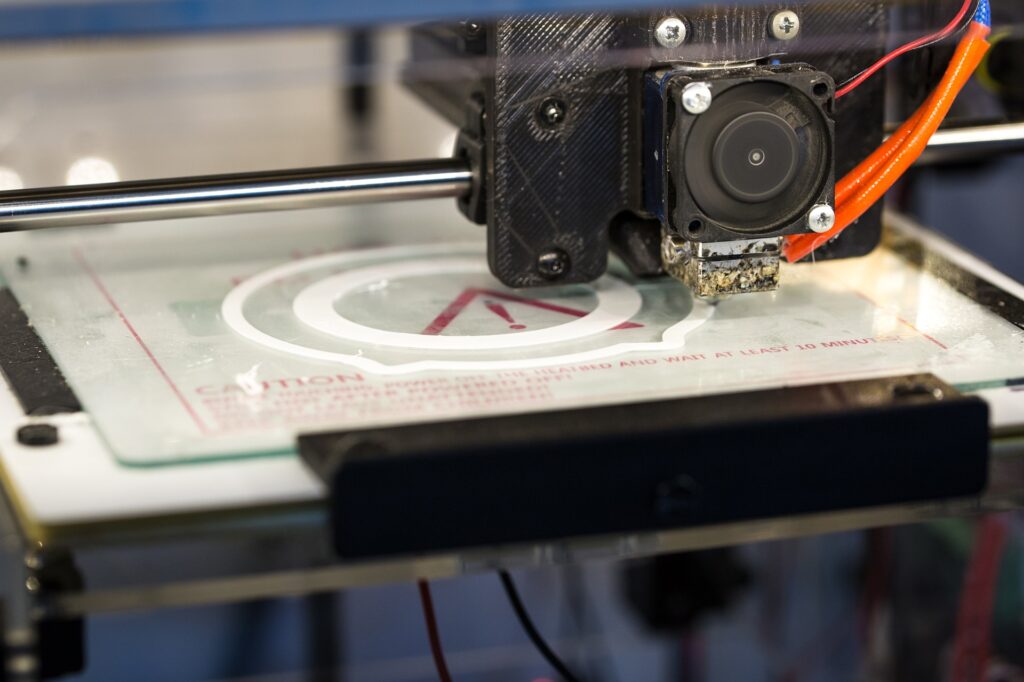

Print bed

The print bed is the part on which the 3D printed object rests. With each new layer, the print bed moves down to accommodate the next layer step. Proper calibration ensures a perfect print without deformation. Printing the first layer without errors is the most important, as it shows if the print bed is properly leveled. It also shows the correct extrusion settings such as quantity, temperature and more. Of great importance is that the print bed ensures sufficient adhesion to the molten material so that the object adheres to the bed.

Hotend

The hot end is where the filament is melted and then extruded through the nozzle. The hot end consists of a feed tube, a heat sink, a heat barrier tube with thermal protection, a heat block, and the nozzle.

The feed tube guides the filament from the extruder down through the heat sink and the heat barrier tube. The top section of the heat block tube is inside the heat sink and feeds the filament through. The bottom section of the thermal barrier tube is connected to the heat block where the filament is melted. Just before this, however, the heat block tube is thinner, and this area is called the heart break. This creates a sudden change in temperature to better control the melting process. All of this is done to ensure that the temperature is lower before the filament reaches the heat block. This process is referred to as heat creep.

Housing

For safety reasons, but also for better temperature management and to ensure good printing results, an enclosure provides a sealed printing environment. This ensures that as few particles as possible are released into the air, making it possible to use the 3D printer in office environments. An enclosure can also minimize printing problems such as deformation and cracking by keeping the internal ambient temperature stable.

Filament

Filament is a spool of thermoplastic (PLA, PETG, ABS) or composite material that is available in different diameters. Depending on the material, a different printing temperature is required and also determines, for example, whether the print bed needs to be heated or not. The most commonly used material for 3D printers is polylactide (PLA), this is mainly due to the relatively uncomplicated processing and the cheapest price.